Passat (B3)

|

General repair instructions

General repair instructions

To ensure perfect and successful gearbox repairs, the greatest care and cleanliness as well as the use of good and proper tools is essential. Obviously, the basis rules for safety are also applicable during repair work. A number of generally valid instructions applicable for the various repair procedures - which were previously repeated a number of times at numerous places in the Workshop Manual - are summarized here. They apply to this Workshop Manual. Gearbox

Notes:

Gaskets, sealing rings

Before installing: Lightly oil outer edge, fill space between sealing lips with grease. After installation:

Locking devices |

|

|

Bolts and nuts

Bearings

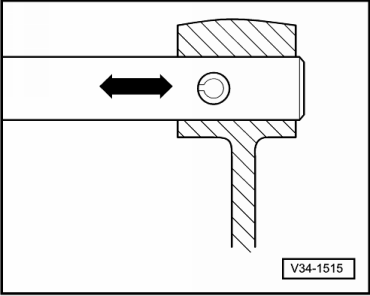

Shims

Synchronizer rings

Gear wheels

|