Passat (B3)

|

|

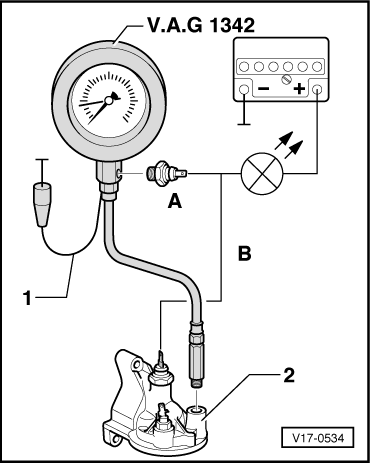

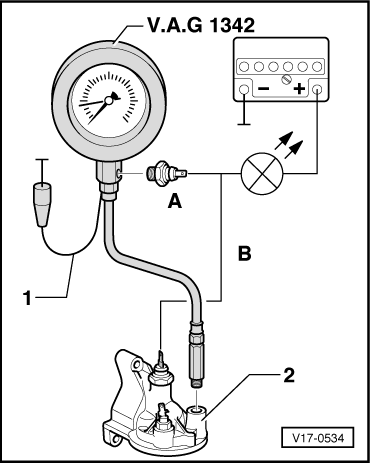

At higher engine speed the oil pressure must not exceed 7.0 bar. If necessary renew oil pump cover with pressure relief valve. |

|

|

At higher engine speed the oil pressure must not exceed 7.0 bar. If necessary renew oil pump cover with pressure relief valve. |