Passat (B3)

|

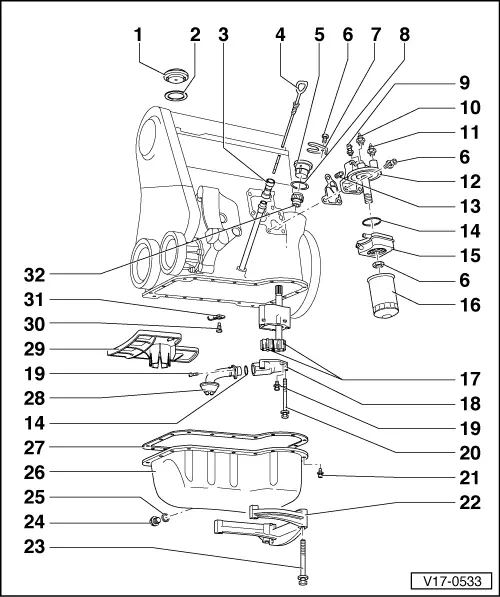

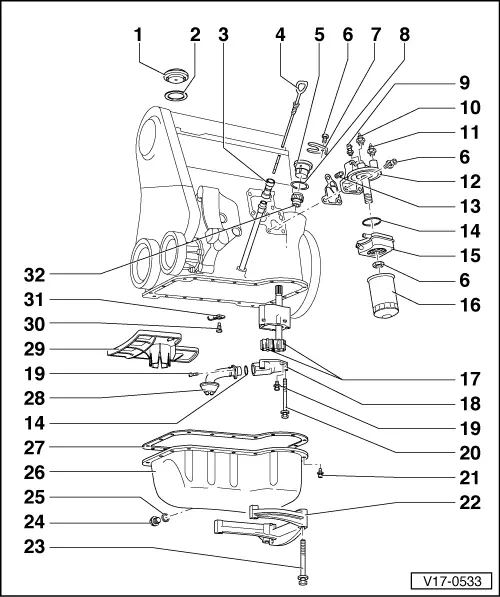

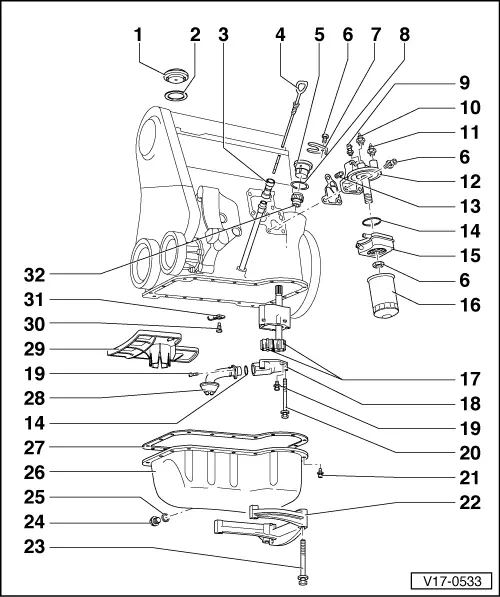

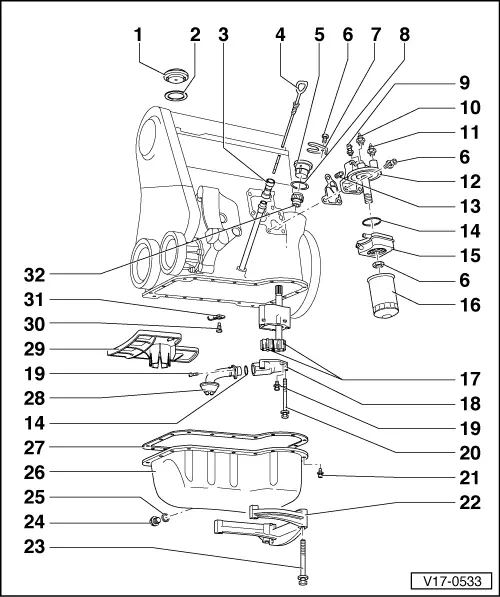

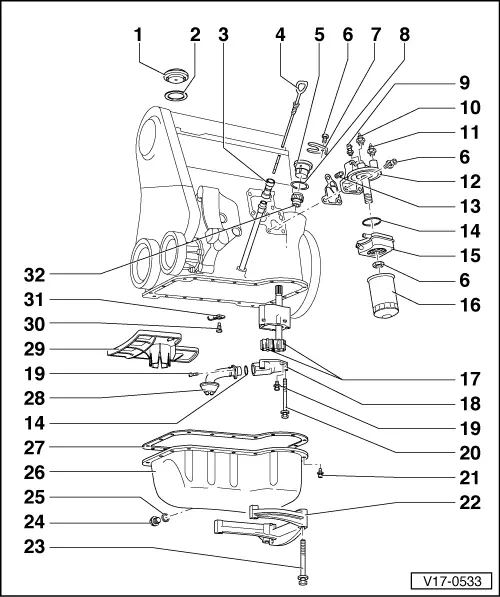

Removing and installing parts of the lubrication system

Removing and installing parts of the lubrication system

Notes:

Checking oil pressure => Page 17-8 Oil system capacity1):

without oil filter 3.8 ltrs. 1) Up-to-date figures: => Emissions test binder Engine oil specifications: Use engine oil to VW standard 500 00 or 501 01. Only in exceptional cases: Multi-grade oils corresponding to API-SF or SG. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

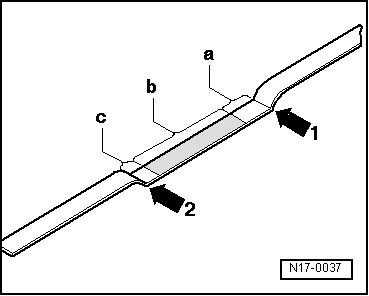

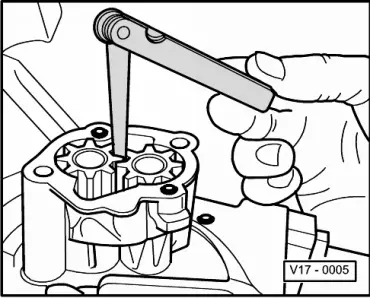

→ Fig. 1 Checking oil pump backlash New: 0.05 mm Wear limit: 0.20 mm |

|

|

|

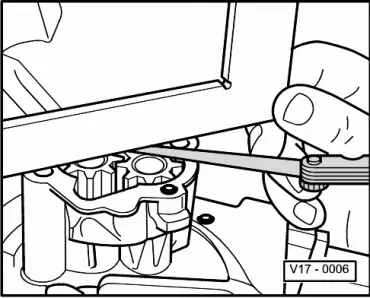

→ Fig. 2 Checking oil pump axial clearance Wear limit: 0.15 mm |