Passat (B3)

|

|

|

|

|

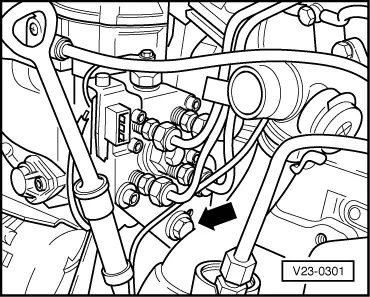

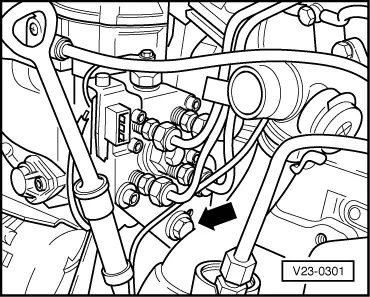

Note: Use open ring spanner 3035 to remove high pressure fuel pipes. |

|

|

|

|

|

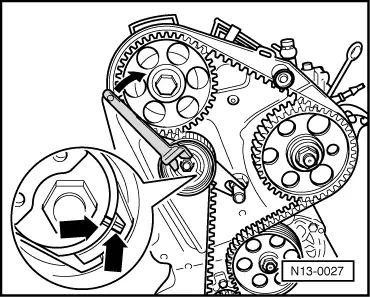

Installing

Note: The commencement of injection is set dynamically with V.A.G 1551. |

|

|

|

|

|

|

|

|

|

|

|

Note: Use open ring spanner 3035 to remove high pressure fuel pipes. |

|

|

|

|

|

Installing

Note: The commencement of injection is set dynamically with V.A.G 1551. |

|

|

|

|

|

|