|

Servicing Diesel direct injection system

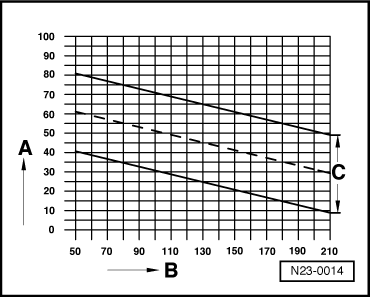

Dynamically checking and adjusting commencement of injection

Special tools, testers, measuring instruments and auxiliary items required

-

◆ Fault reader V.A.G 1551 or vehicle system tester V.A.G 1552 with cable V.A.G 1551/3

-

◆ Ring spanner 3035

-

◆ Torque wrench V.A.G 1331 (5...50 Nm)

Notes:

-

◆ Dynamically checking and correcting commencement of injection is only possible in function 04 "Engine basic setting".

-

◆ The commencement of injection must always be checked after renewing the toothed belt or loosening the injection pump bolts or toothed belt sprockets and if necessary adjusted.

Checking and adjustment conditions

-

● Mechanical engine basic setting OK.

-

● Toothed belt tension OK.

-

‒ Connect fault reader V.A.G 1551 and select engine electronics control unit (address word 01); carry out selection with engine idling.

|