-

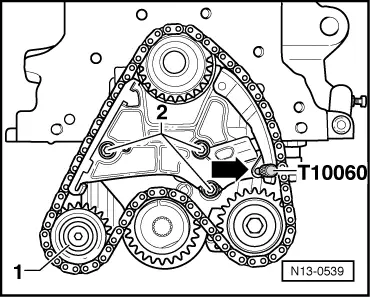

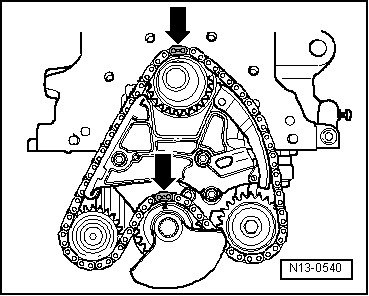

‒ → Block the counterbalance shaft as shown with a spanner (24/27 mm AF) -1-.

Note:

When blocking the counterbalance shaft, make sure that the spanner is centred on the counterbalance weight and at right angles to counterbalance shaft.

-

‒ Loosen securing bolt -2- of counterbalance weight.

Note:

Only loosen counterbalance weight securing bolt -2-; do not remove it.

-

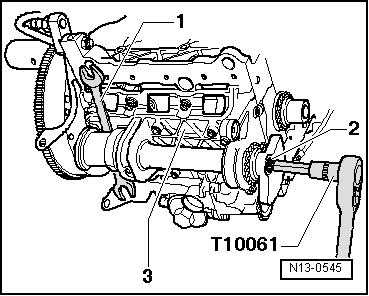

‒ Unbolt retaining frame -3- from cylinder block and remove retaining frame with counterbalance shaft.

-

‒ Lay retaining frame aside on a clean surface.

-

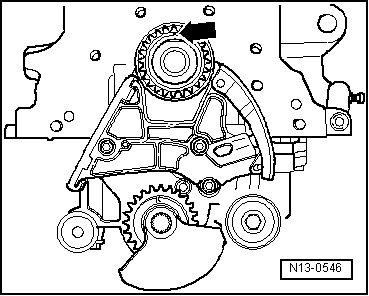

‒ Remove securing bolt from counterbalance shaft.

-

‒ Remove counterbalance weight and sprocket from counterbalance shaft.

-

‒ Turn the counterbalance shaft so that it can be removed from the bearing.

Installing

-

‒ Oil bearing's running surfaces.

-

‒ Set counterbalance shaft in bearing.

-

‒ Fit sprocket and counterbalance weight on counterbalance shaft.

Note:

The assembly of the sprocket and the counterbalance weight is possible in one position only.

-

‒ Hand tighten securing bolt for counterbalance weight and sprocket.

-

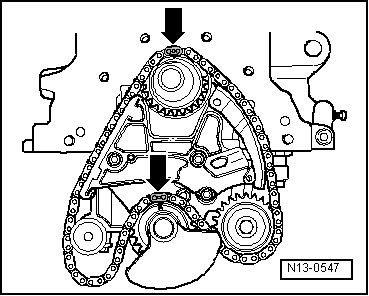

‒ Tighten retaining frame to cylinder block by hand so that there is no play.

Notes:

-

◆ When fitting retaining frame, ensure that the dowel sleeve is inserted in the cylinder block and the O ring is fitted in the retaining frame.

-

◆ Align the retaining frame so that it fits flush with the outer edge of the cylinder block on the pulley end.

-

‒ Bolt retaining frame with counterbalance shaft to cylinder block

Tightening torque: 20 Nm.

-

‒ Check that retaining frame aligns flush with outer edge of cylinder block on the pulley end.

|