Polo Mk3

|

|

|

Up to 26.04.95 From 27.04.95

|

|

|

|

|

|

Vehicles with cable selector control:

|

|

|

|

|

|

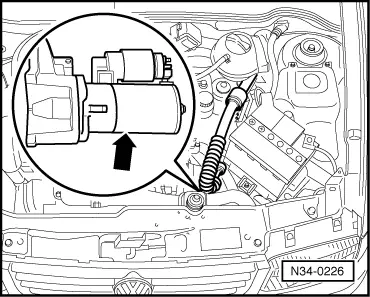

=> Repair group 27; Removing and installing starter. For vehicles with an oval air cleaner:

|

|

|

|

|

|

Vehicles with petrol engine and rod selector mechanism |

|

|

|

|

|

Vehicles with petrol engine and cable selector mechanism |

|

|

|

|

|

|

|

|

|

Continuation for all vehicles

|

|

|

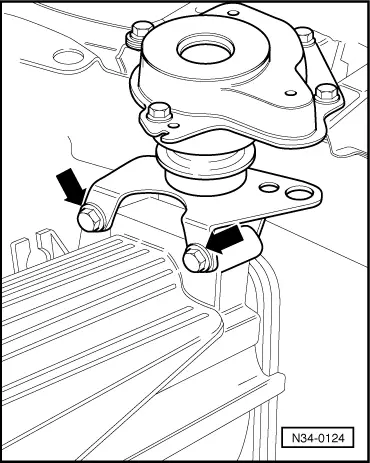

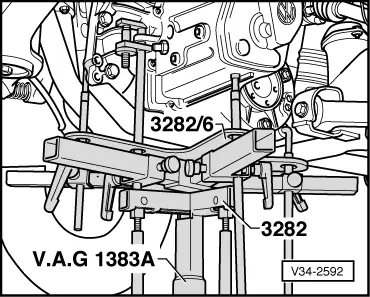

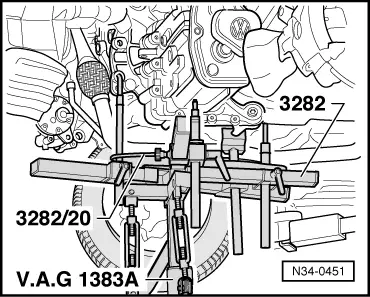

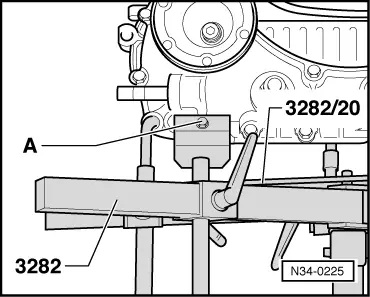

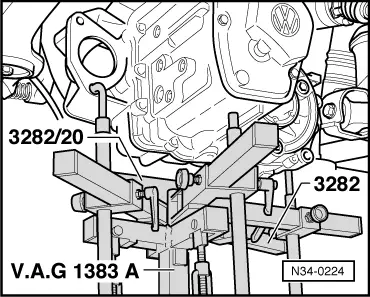

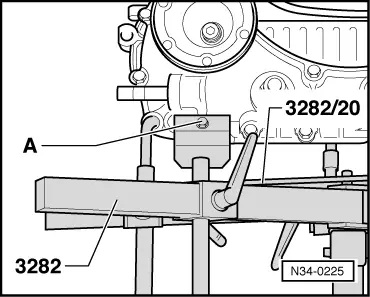

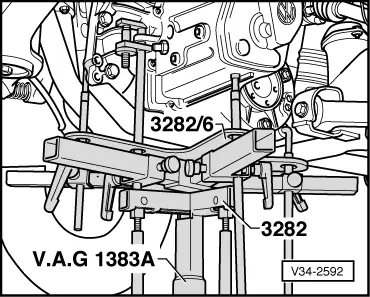

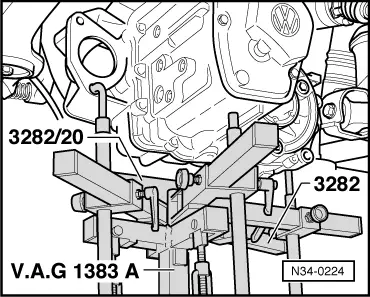

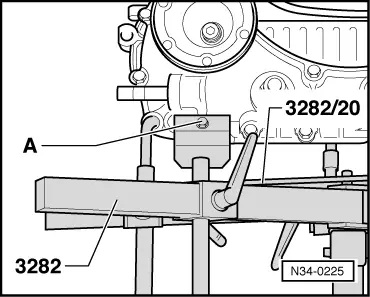

The pin hole is required to secure gearbox to gearbox mounting 3282 . |

|

|

|

|

|

|

|

|

|

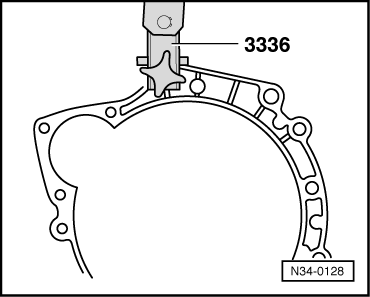

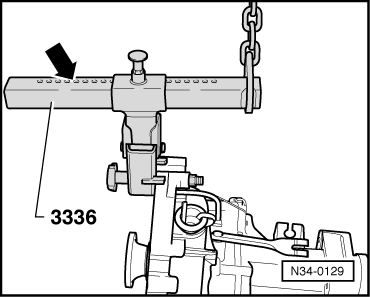

Transporting the automatic gearbox Special tool 3336 may be used to transport the gearbox and also when setting up gearbox mounting 3282.

|

|

|

No. of holes visible = 9

Installing Note: Modifications on vehicles with Diesel engine .

The clutch plate must be able to slide lightly to and fro on the input shaft.

|

|

|

|

|

|

|

|

|

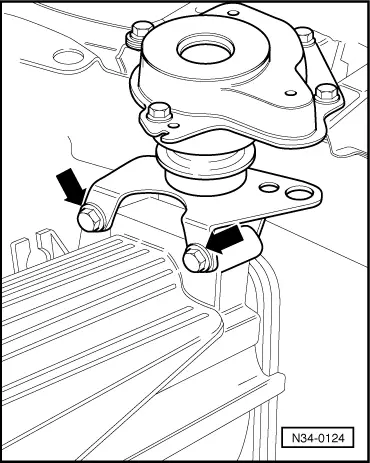

Warning!

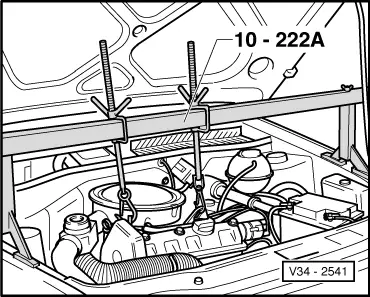

Do not remove support bar 10-222A until the bolts securing the left-hand gearbox console have been tightened to torque setting.

|

|

|

=> Repair group 27; Removing and installing starter.

|

|

|

|

|

|

|

|

|

Vehicles with cable selector control:

|

|

|

|

|

|

|

|

|

|

Notes:

Up to 26.04.95 =>from Page 30-10 From 27.04.95 =>from Page 30-17

Note: Note radio coding for vehicles with coded radio.

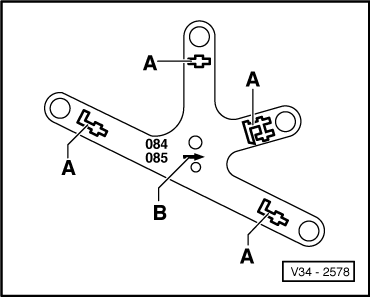

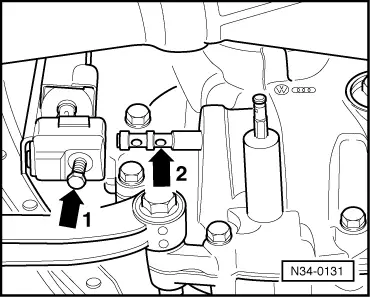

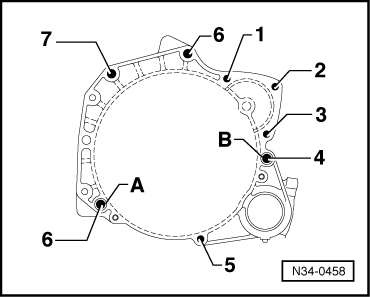

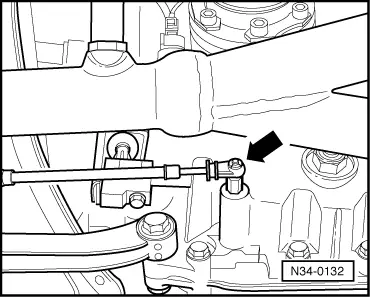

Rod selector mechanism . Cable selector mechanism => Page 34-41 Tightening torques Gearbox to engine |

|

|||||||||||||||||||||||||||||

|

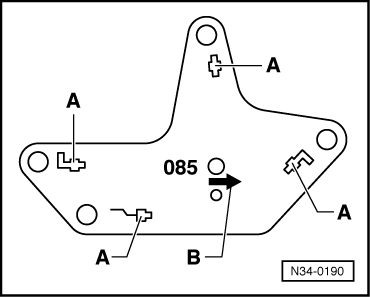

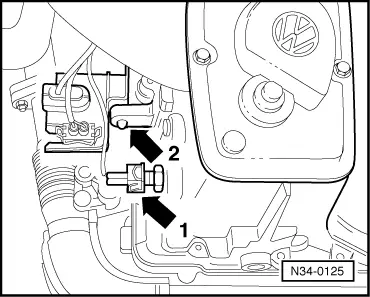

→ Engine block of cast iron (painted black)

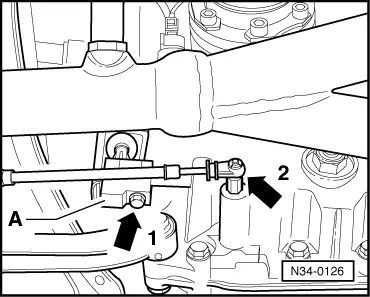

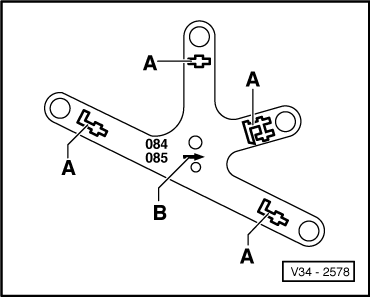

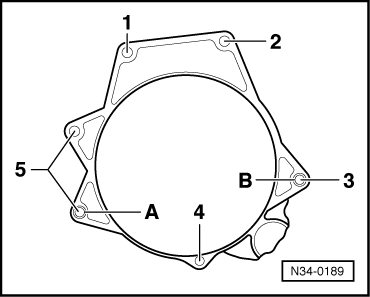

Items A + B - Dowel sleeves Gearbox to engine |

|

|||||||||||||||||||||||||||||||||

|

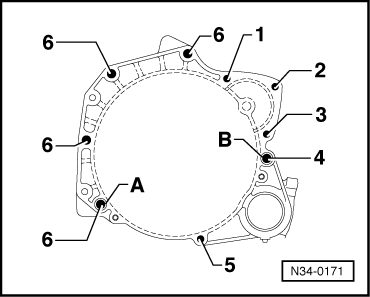

→ Engine block of aluminium (metallic brilliant)

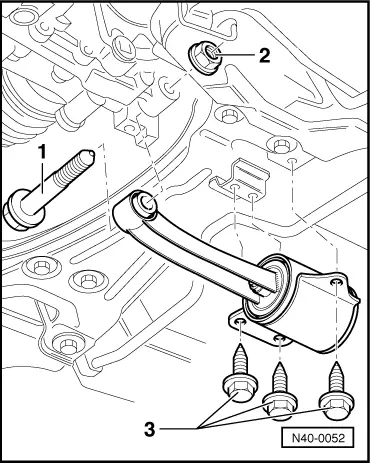

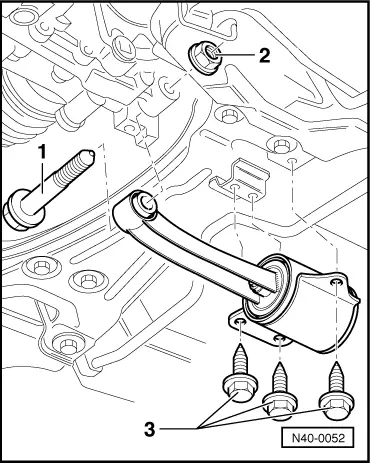

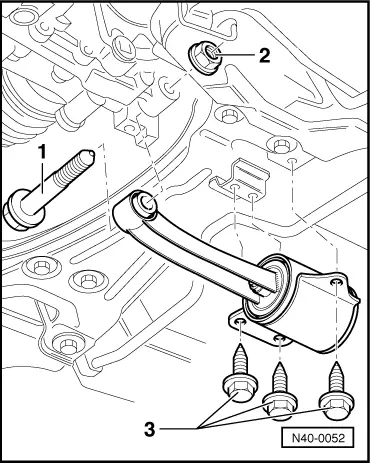

1) Flywheel shield securing bolts Items A + B - Dowel sleeves Assembly mountings |

|

||||||||||||

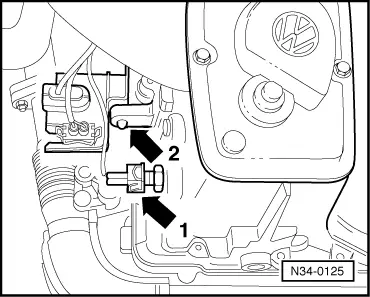

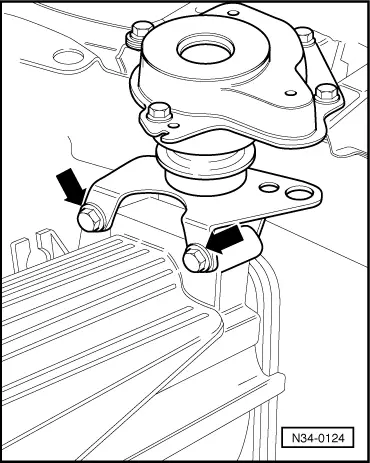

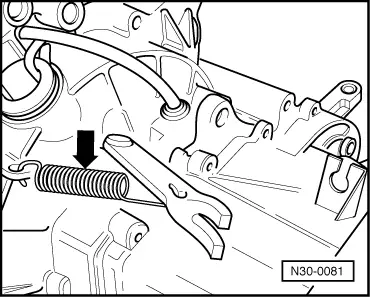

Modification from 12.96 From vehicle identification No.: 6N ZVW 133102 modified hexagon bolts -3- have been introduced.

| ||||||||||||

|

|||

| |||

|

|||||||||

| |||||||||

|

|

|

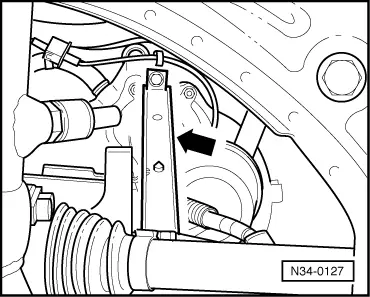

The following modifications should be noted on vehicles with Diesel engine:

|

|

|

|

|

|

|

|

|

|

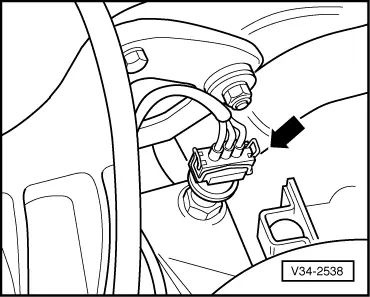

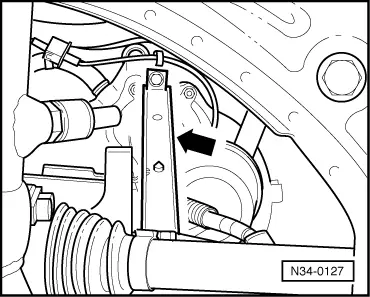

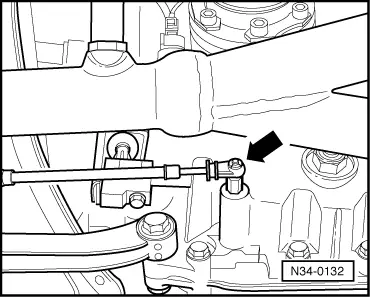

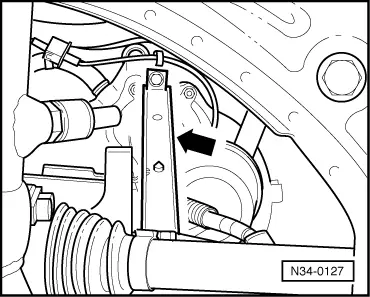

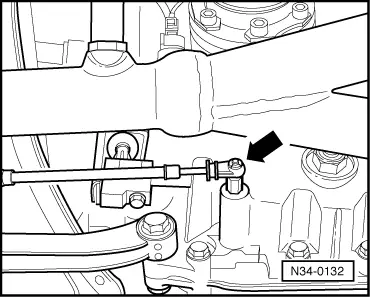

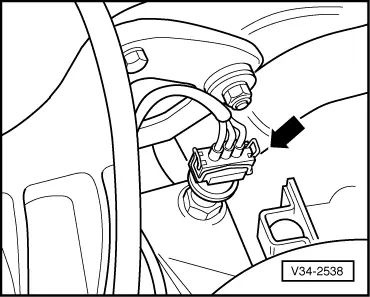

→ Install starter (arrow) before installing gearbox. => Repair group 27; Removing and installing starter. The clutch housing flange and the securing bolts have been matched to the Diesel engine. Tightening torques |

|

|||||||||||||||||||||||||

|

→ Gearbox to engine

1) Flywheel shield securing bolts 2) Also starter to gearbox Items A + B = Dowel sleeves |