Polo Mk3

|

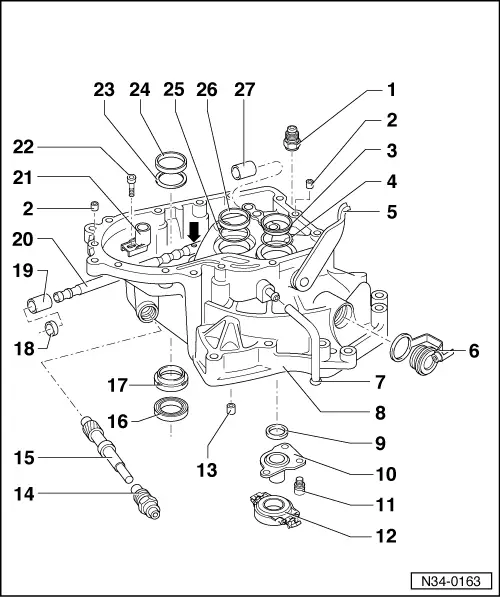

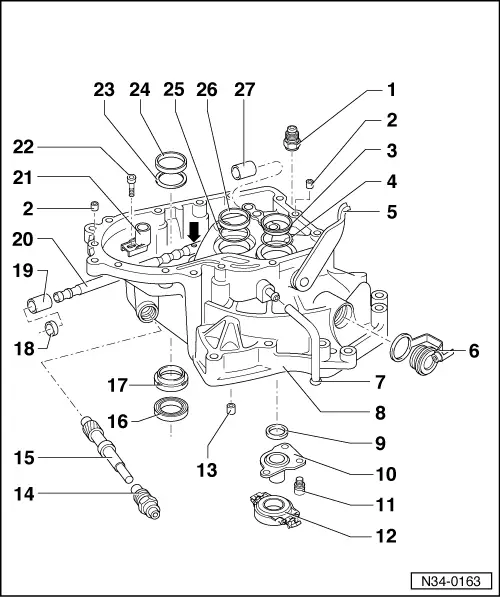

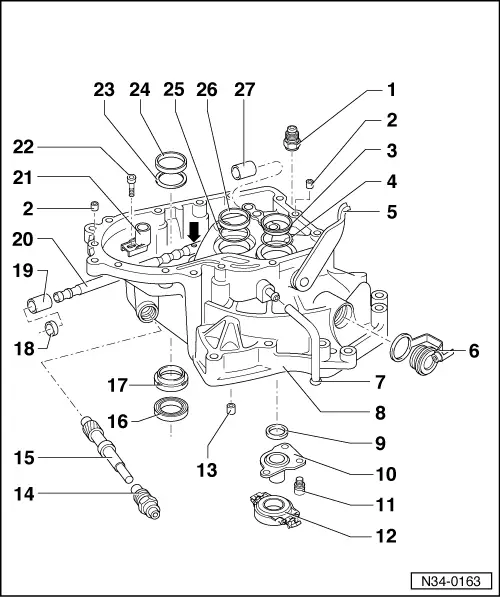

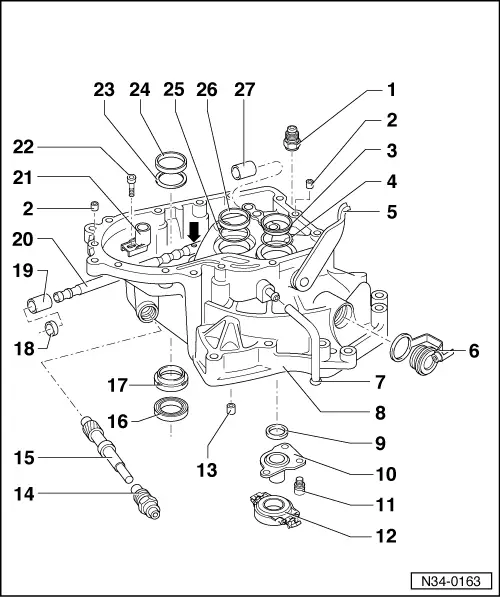

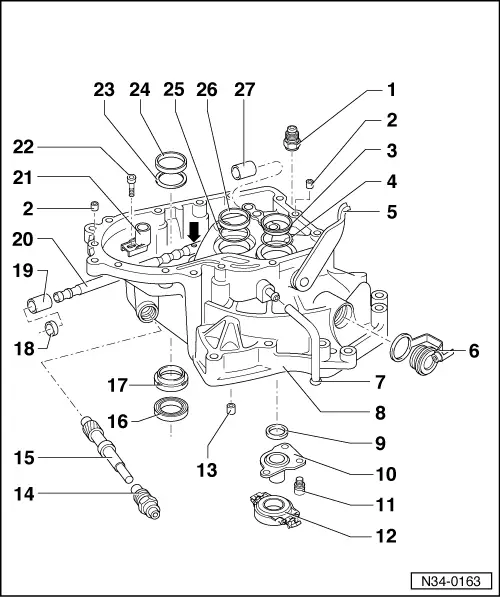

Servicing clutch housing

Servicing clutch housing

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

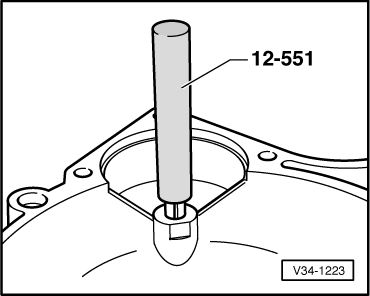

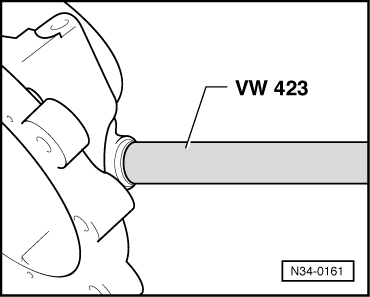

→ Fig.3 Pulling out output shaft oil seal. |

|

|

|

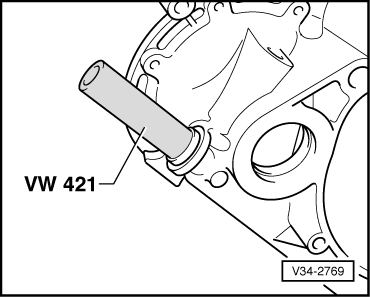

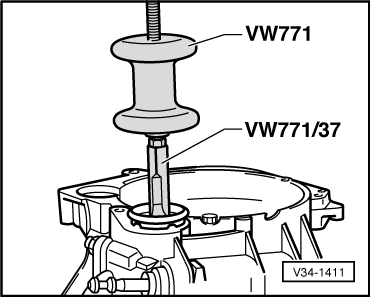

→ Fig.4 Driving in output shaft oil seal. Installation position: 2.5 mm below housing upper surface. |

|

|

|

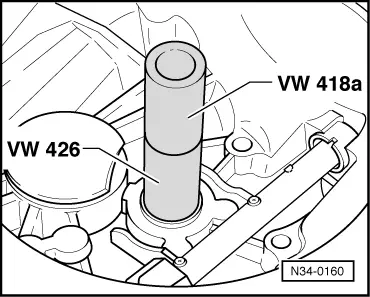

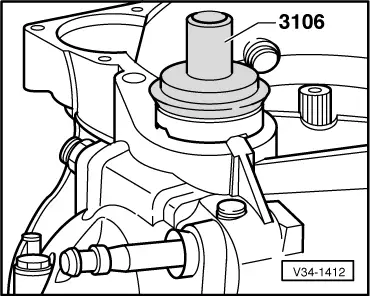

→ Fig.5 Pulling out starter bush. |

|

|

|

→ Fig.6 Driving in starter bush.

|

|

|

|

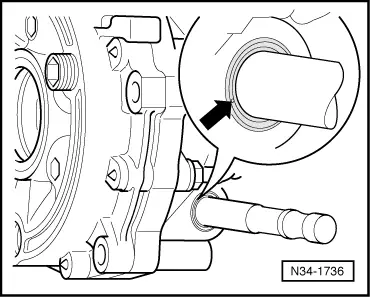

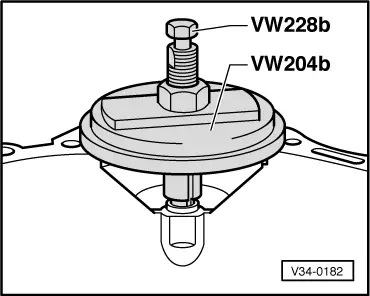

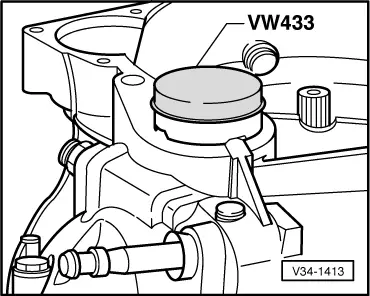

→ Fig.7 Pulling in flange shaft oil seal. |

|

|

|

→ Fig.8 Driving in flange shaft oil seal.

|

|

|

|

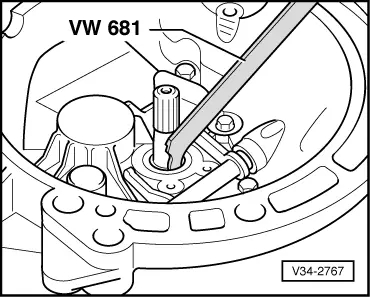

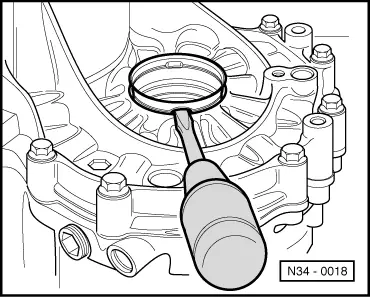

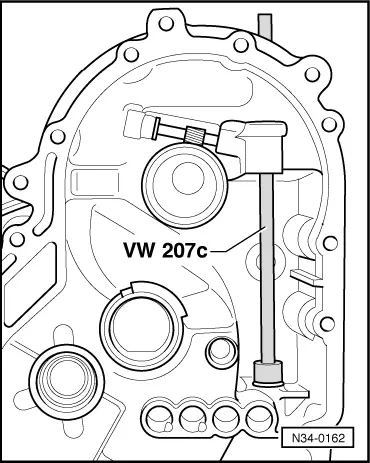

→ Fig.9 Lever out sleeve with screwdriver |

|

|

|

→ Fig.10 Driving in sleeve |

|

|

|

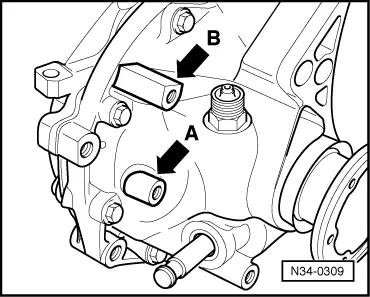

→ Fig.13 Removing and installing front ball sleeve Installation position: 10 mm below housing upper surface. |

|

|

|

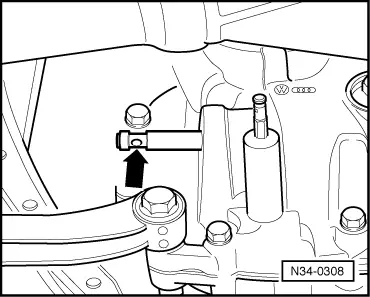

→ Fig.14 Removing and installing rear ball sleeve Installation position: The ball sleeve must be flush in the rear area with the mounting eye. |