|

Gearbox: Electrical check

Test table for vehicles up to > 09.99 (with 45-pin control unit connector)

|

Switch to voltage measuring range 20 V

|

|

Test step

|

V.A.G 1598/18 sockets

|

Test of

|

▪ Test conditions

- Additional operations

|

Specified value

|

Rectifying fault

|

|

1

|

45 + 1

23 + 1

|

Supply voltage for control unit -J217-

(terminal 15)

|

▪ Ignition switched on

|

approx. battery voltage

|

- Check wiring using current flow diagram

Check wiring from contact 1 to earth

Check wiring from contact 45 + 23 to terminal 15 central electrics

|

|

|

22 + 1

|

Supply voltage for fault memory in control unit -J217-

(terminal 30)

|

|

approx. battery voltage

|

- Check wiring from contact 22 to terminal 30 central electrics

|

|

Switch to voltage measuring range 20 V

|

|

Test step

|

V.A.G 1598/18 sockets

|

Test of

|

▪ Test conditions

- Additional operations

|

Specified value

|

Rectifying fault

|

|

2

|

6 + 1

|

Selector lever lock solenoid -N110-

|

▪ Ignition switched off

|

0 V

|

- Check wiring using current flow diagram

|

|

|

|

|

▪ Ignition switched on

|

approx. battery voltage

|

|

|

|

Bridge

6 + 1

|

|

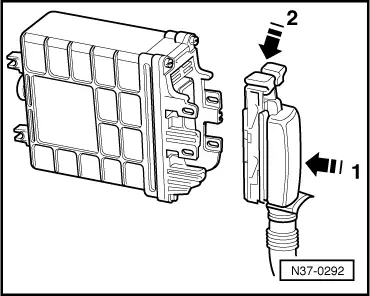

- Connect test unit V.A.G 1526

▪ Ignition switched on

Connect bridge with cables from V.A.G 1594

|

Solenoid must audibly click

|

- Renew selector lever lock solenoid -N110-

=> Repair group 37; Servicing selector mechanism

|

|

3

|

21 + 1

|

Brake light switch -F-

|

▪ Brake pedal not depressed

|

0 V

|

- Check wiring according to current flow diagram

Renew brake light switch -F-

|

|

|

|

|

- Brake pedal depressed

|

approx. battery voltage

|

=> Running gear, self-diagnosis for ABS; Repair group 01; Electrical/electronic components and locations

|

|

Switch to voltage measuring range 20 V

|

|

Test step

|

V.A.G 1598/18 sockets

|

Test of

|

▪ Test conditions

- Additional operations

|

Specified value

|

Rectifying fault

|

|

4

|

42 + 1

|

Multi-function switch -F125-

|

- Selector lever position P

|

approx. battery voltage

|

- Check connector on multi-function switch above gearbox for contact corrosion, renew if necessary

|

|

|

|

|

▪ Selector lever position R, N, D, 3, 2, 1

|

0 -1 V

|

- Adjust multi-function switch -F125-

|

|

|

40 + 1

|

Multi-function switch -F125-

|

▪ Selector lever position R

|

approx. battery voltage

|

- Check wiring according to current flow diagram

|

|

|

|

|

▪ Selector lever position P, N, D, 3, 2, 1

|

0 -1 V

|

- Renew multi-function switch -F125-

|

|

|

41 + 1

|

Multi-function switch -F125-

|

▪ Selector lever position N

|

approx. battery voltage

|

|

|

|

|

|

▪ Selector lever position P, R, D, 3, 2, 1

|

0 -1 V

|

|

|

Continued on next page

|

|

Switch to voltage measuring range 20 V

|

|

Test step

|

V.A.G 1598/18 sockets

|

Test of

|

▪ Test conditions

- Additional operations

|

Specified value

|

Rectifying fault

|

|

4

|

44 + 1

|

Multi-function switch -F125-

|

- Selector lever position D

|

approx. battery voltage

|

- Check connector on multi-function switch above gearbox for contact corrosion, renew if necessary

|

|

|

|

|

▪ Selector lever position P, R, N, 3, 2, 1

|

0 -1 V

|

- Adjusting multi-function switch -F125-

|

|

|

43 + 1

|

Multi-function switch -F125-

|

▪ Selector lever position 3

|

approx. battery voltage

|

- Check wiring according to current flow diagram

|

|

|

|

|

▪ Selector lever position P, R, N, D, 2, 1

|

0 -1 V

|

- Renew multi-function switch -F125-

|

|

|

19 + 1

|

Multi-function switch -F125-

|

▪ Selector lever position 2

|

approx. battery voltage

|

=> Automatic gearbox 001; Repair group 37; Electrical/electronic components and locations; Components on gearbox

|

|

|

|

|

▪ Selector lever position P, R, N, D, 3, 1

|

0 -1 V

|

|

|

|

18 + 1

|

Multi-function switch -F125-

|

▪ Selector lever position 1

|

approx. battery voltage

|

|

|

|

|

|

▪ Selector lever position P, R, N, D, 3, 2

|

0 -1 V

|

|

|

Switch to resistance measuring range 200 ω

|

|

Test step

|

V.A.G 1598/18 sockets

|

Test of

|

▪ Test conditions

- Additional operations

|

Specified value

|

Rectifying fault

|

|

5

|

20 + 1

|

Kickdown switch

-F8-

|

▪ Ignition switched off

|

infinite ω1)

|

- Check wiring on basis of current flow diagram

|

|

|

|

|

▪ Accelerator not depressed

|

|

- Adjust accelerator cable or renew

|

|

|

|

|

- Depress accelerator as far as kickdown

|

less than 1.5 ω

|

|

1)

Switch V.A.G 1526 to highest ω range

|

Switch to resistance measuring range 2 k ω

|

|

Test step

|

V.A.G 1598/18 sockets

|

Test of

|

▪ Test conditions

- Additional operations

|

Specified value

|

Rectifying fault

|

|

6

|

35 + 36

|

Road speed sender -G68-

|

min.

|

0.4 kω

|

- Check wiring on basis of current flow diagram

|

|

|

|

|

max.

|

0.6 kω

|

- Renew road speed sender -G68-

|

|

Switch to resistance measuring range 20 k ω

|

|

Test step

|

V.A.G 1598/18 sockets

|

Test of

|

▪ Test conditions

- Additional operations

|

Specified value

|

Rectifying fault

|

|

7

|

9 + 10

|

Gearbox speed sender -G38-

|

min.

|

0.4 kω

|

- Check wiring on basis of current flow diagram

|

|

|

|

|

max.

|

0.6 kω

|

- Renew gearbox speed sender -G38-

|

|

Switch to resistance measuring range 200 ω

|

|

Test step

|

V.A.G 1598/18 sockets

|

Test of

|

▪ Test conditions

- Additional operations

|

Specified value

|

Rectifying fault

|

|

8

|

7 + 1

|

Solenoid valve 1 -N88-

|

▪ Ignition switched off

|

9 to 24 ω

|

- Check wiring according to current flow diagram, renew if necessary

|

|

9

|

8 + 1

|

Solenoid valve 2 -N89-

|

▪ Ignition switched off

|

9 to 24 ω

|

|

|

10

|

26 + 1

|

Solenoid valve 3 -N90-

|

▪ Ignition switched off

|

9 to 24 ω

|

|

|

11

|

25 + 1

|

Solenoid valve 4 -N91-

|

▪ Ignition switched off

|

9 to 24 ω

|

|

|

12

|

3 + 1

|

Solenoid valve 6 -N93-

|

▪ Ignition switched off

Separate connector for series resistance -N207-

|

2 to 5 ω

|

|

|

13

|

Measure at component

|

Series resistance -N207-

|

- Remove resistance connection from bracket on top of gearbox and separate

Measure at connector with cable

|

10 to 15 ω

|

" "

If the value is not attained:

Renew resistance

|

|

Switch to resistance measuring range 20 k ω

|

|

Test step

|

V.A.G 1598/18 sockets

|

Test of

|

▪ Test conditions

- Additional operations

|

Specified value

|

Rectifying fault

|

|

14

|

33 + 34

|

Gearbox oil temperature sender

-G93- (ATF)

|

▪ Ignition switched off

|

|

- Check wiring on basis of current flow diagram

|

|

|

|

|

▪ ATF temperature

|

|

|

|

|

|

|

approx. 30 °C

|

2.2 k ω

|

|

|

|

|

|

- Switch hand multimeter V.A.G 1526 to 2 k ω

approx. 70° C

approx. 110° C

|

0.5 k ω

0.2 k ω

|

|

|