| –

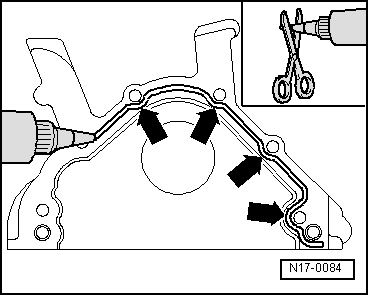

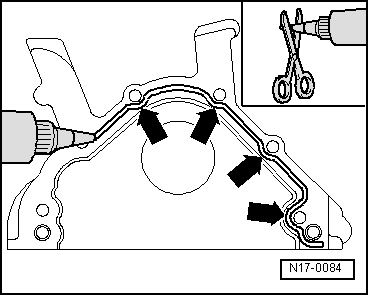

| Cut off tube nozzle at forward marking (nozzle Ø approx. 3 mm). |

| –

| Apply silicone sealing compound, as shown, to clean sealing flange sealing surface. Sealant bead must be: |

| t

| The sealant bead should be -arrows-: 2...3 mm thick |

Note | t

| Sealant bead should not be thicker, as otherwise excess sealant can enter the sump and clog the strainer in the oil pump suction pipe, as well as drip onto the crankshaft oil seal. |

| t

| Before applying sealant bead, cover sealing surface of oil seal with a clean rag. |

| –

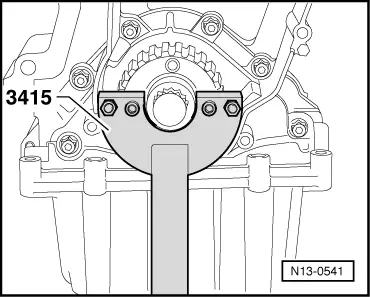

| Fit sealing flange immediately and lightly tighten all bolts. |

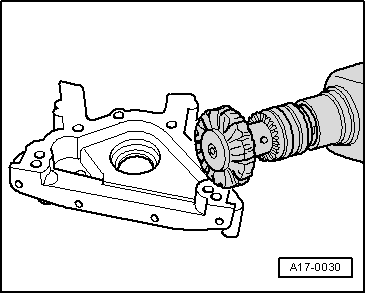

Note | When fitting sealing flange with oil seal installed, use guide sleeve -T10053/1-. |

| –

| Tighten sealing flange securing bolts diagonally and alternately. Torque setting: 15 Nm |

Note | Sealing compound must dry for approx. 30 minutes after installation. Only then fill with engine oil. |

| Installing toothed belt and adjusting valve timing → Chapter. |

|

|

|

Note

Note

Note

Note Note

Note Note

Note