Polo Mk4

| Input shaft - dismantle and assemble |

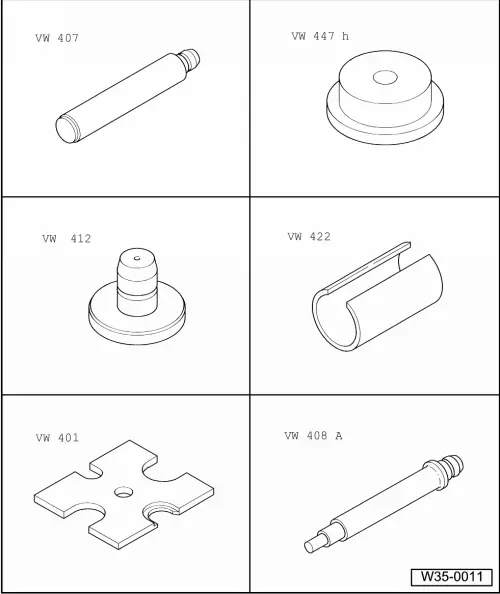

| Special tools and workshop equipment required |

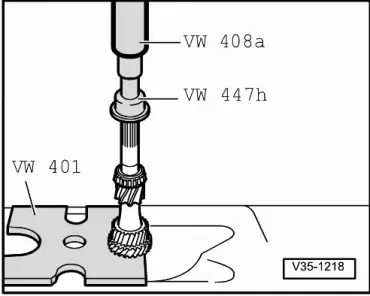

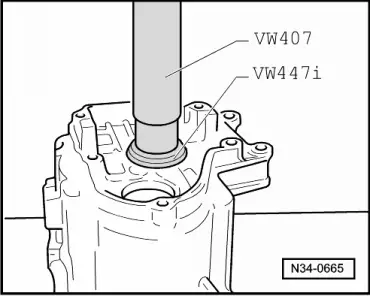

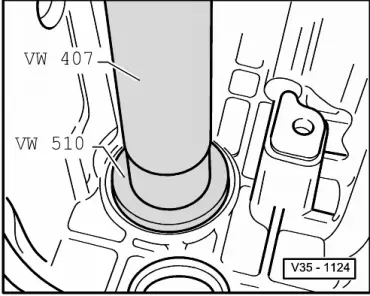

| t | Pressure pin -VW 407- |

| t | Pressure disc -VW 447 H- |

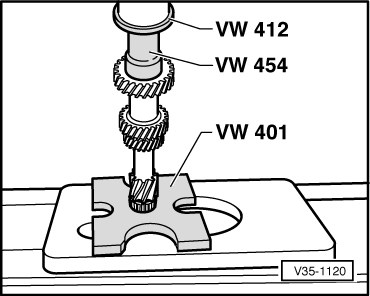

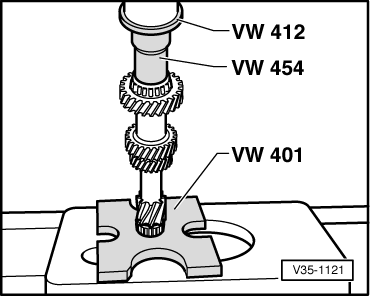

| t | Pressure disc -VW 412- |

| t | Tube -VW 422- |

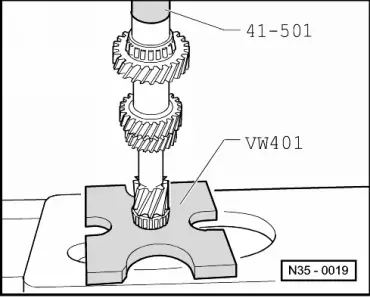

| t | Plate -VW 401- |

| t | Plate -VW 402- |

| t | Pressure pin -VW 408A- |

| t | Tube -VW 421- |

| t | Pressure tube -VW 454- |

| t | Pressure disc -VW 447 i- |

| t | Bracket -VW 540- |

| t | Installation collar -41-501- |

| t | Separating device -KUKKO 17/1- |

Note

Note

|

| 1 - | Clutch housing |

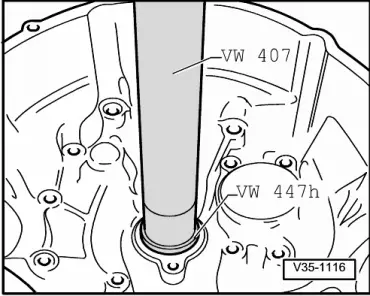

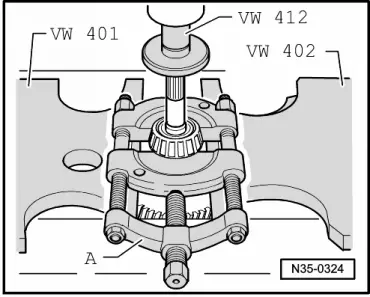

| 2 - | Outer race/taper roller bearing |

| q | Remove → Fig. |

| q | Install → Fig. |

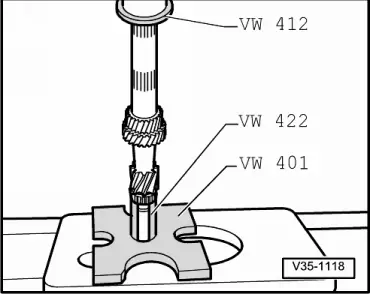

| 3 - | Taper roller bearing inner race |

| q | Remove → Fig. |

| q | Install → Fig. |

| 4 - | Input shaft |

| q | Adjust → Chapter |

| 5 - | 3rd gear wheel |

| q | Shoulder points to 4th. gear |

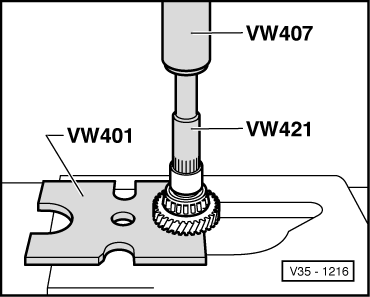

| q | Remove → Fig. |

| q | Install → Fig. |

| 6 - | Circlip |

| q | Always renew |

| 7 - | 4th gear wheel |

| q | Pressing off with taper roller bearing outer race and sleeve → Fig. |

| q | Install → Fig. |

| q | Shoulder points to 3rd. gear. |

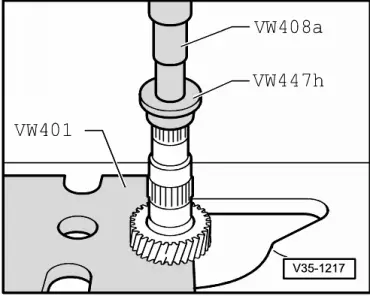

| 8 - | Taper roller bearing inner race |

| q | Remove with 4th. gear and sleeve → Fig. |

| q | Install → Fig. |

| 9 - | Thrust washer |

| 10 - | Outer race/taper roller bearing |

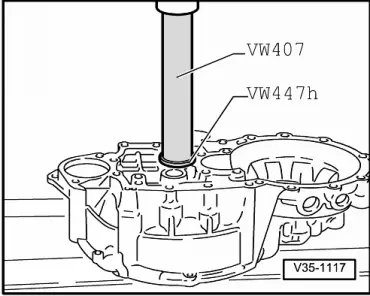

| q | Remove → Fig. |

| q | Install → Fig. |

| 11 - | Adjustment shim |

| q | Determining thickness: adjusting input shaft → Chapter |

| 12 - | Gearbox housing |

| 13 - | Bushing |

| q | For needle roller bearing. |

| q | Press off with 4th gear wheel and taper roller bearing inner race → Fig. |

| q | Install → Fig. |

| q | Place thrust washer on before installing ( → Item) |

| 14 - | Needle roller bearing |

| 15 - | 5th gear wheel |

| q | Remove together with synchro hub from 5th gear → Chapter |

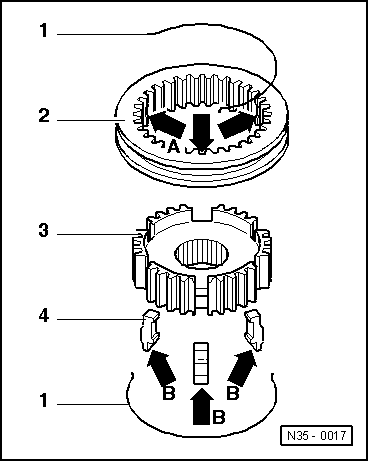

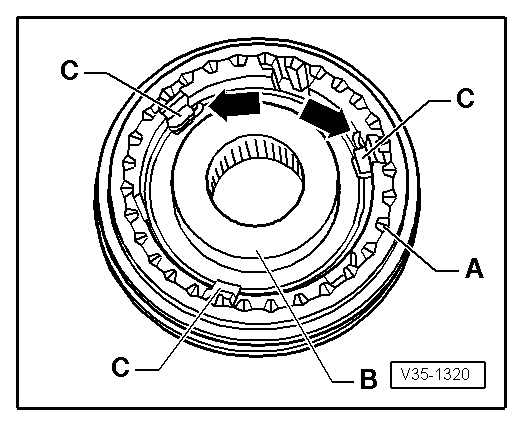

| 16 - | 5nd gear synchro-ring |

| q | With cast locking pieces → Fig. |

| q | Check wear → Fig. |

| 17 - | Spring |

| q | Installation position → Fig. |

| 18 - | Locking pieces (3 units) |

| q | Installation position → Fig. |

| 19 - | Synchro-hub of the 5th gear |

| q | Remove and install → Chapter. |

| 20 - | Locking collar of the 5th gear |

| q | Remove and install → Chapter. |

| 21 - | Spring washer |

| q | Installation position → Fig. |

| 22 - | M10 Torx screw, 80 Nm |

| q | Fitted piece on bolt head locates dished spring → Fig. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|