| –

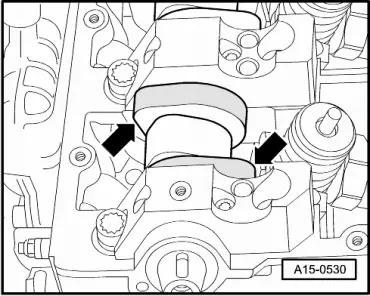

| After affixing the head, turn valve command shaft in such a way that cams for cylinder 1 point homogeneously upwards. Before installing indented belt, place crankshaft in PMS in the engine rotation direction → Chapter, Indented belt - remove and install, adjust. |

| –

| Install valve command shaft gear cube. → Chapter, Valve command shaft - remove and install |

| –

| Perform test drive and consult fault memory → Chapter; check and erase engine command unit fault memory. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note