Polo Mk4

|

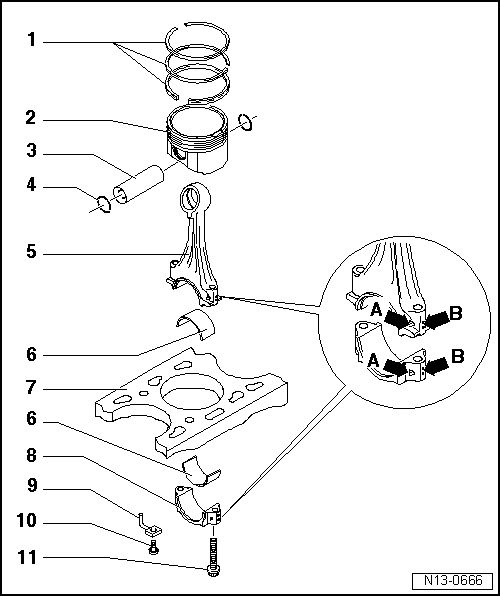

| 1 - | Piston rings |

| q | Displace the opening by 120°. |

| q | Remove and install with ring pliers. |

| q | Reference “TOP” pointing towards the piston head. |

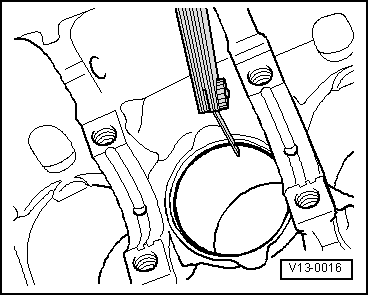

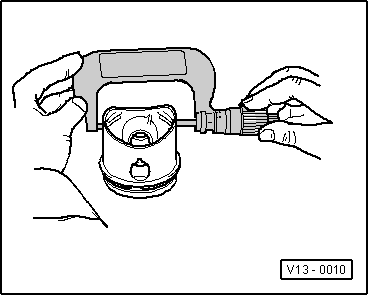

| q | Check opening between ends. → Fig. |

| q | Check ring clearance in the piston channel. → Fig. |

| 2 - | Piston |

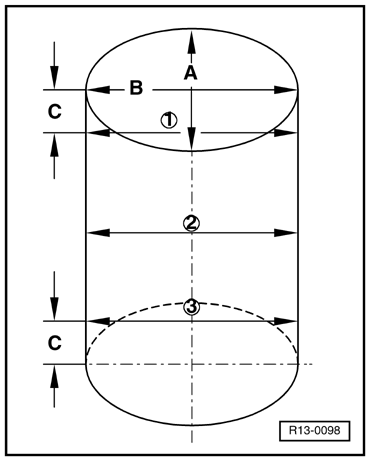

| q | Check → Fig. |

| q | Mark correspondence with the cylinder. |

| q | The arrow on piston head points to the pulley side. |

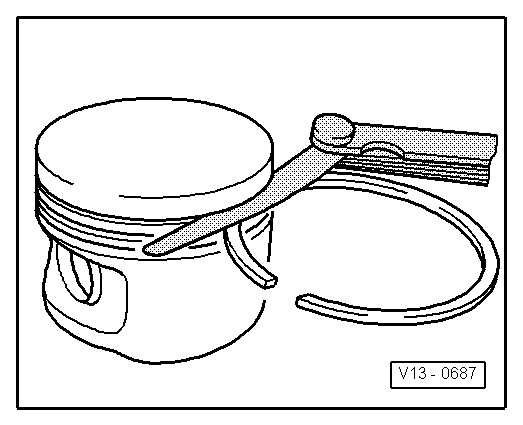

| q | Install with the ring tensioning strap. |

| 3 - | Piston pin |

| q | In case of difficulties in the removal, heat the piston to 60° C. |

| q | Remove and install by using the Puller and Fitter - VW 222A-. |

| 4 - | Retaining ring |

| q | Replace. |

| 5 - | Connecting rod |

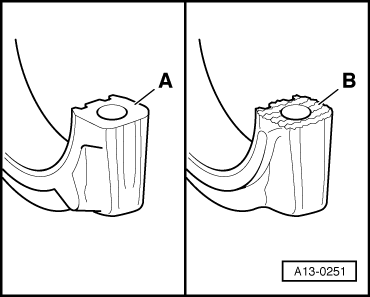

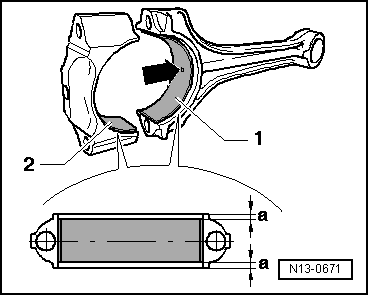

| q | With splitting (breaking) → Fig. |

| q | Only replace by complete set. |

| q | Mark correspondence with cylinder -B-. |

| q | Installation position: Markings -A- point towards the pulley side. |

| 6 - | Bearing shell |

| q | Check the installation position → Fig. |

| q | Place bearing shells centered. |

| q | Do not invert bearing shells already used. |

| q | Ensure it is firmly fastened. |

| q | Clearance in the groove (new): 0.10...00.35 mm, Wear limit: 0.40 mm. |

| q | Measure radial clearance with “Plastigage” (new): 0.01...00.05 mm, Wear limit: 0.09 mm. Do not rotate the crankshaft when measuring radial gap. |

| 7 - | Engine block |

| q | Check cylinder diameter → Fig. |

| q | Measures of the pistons and cylinders → Chapter. |

| 8 - | Connecting rod cap |

| q | Pay attention on the installation position. |

| q | Due to splitting (breaking) of the connecting rods, the cap only seats in one position and with the corresponding connecting rod. |

| 9 - | 30 Nm 90° |

| q | Replace after each removal. |

| q | Lubricate the thread and the contact surface with oil. |

| q | To measure the radial clearance, tighten to 30 Nm only, without angular torque. |

|

| 1 - | Segment rings |

| q | Displace the opening by 120°. |

| q | Remove and install with ring pliers. |

| q | Reference “TOP” pointing towards the piston head. |

| q | Check opening between ends → Fig. |

| q | Check ring clearance in the piston channel → Fig. |

| 2 - | Piston |

| q | Check → Fig. |

| q | Mark correspondence with the cylinder. |

| q | The arrow on piston head points to the pulley side. |

| q | Install with the ring tensioning strap. |

| 3 - | Piston pin |

| q | In case of difficulties in the removal, heat the piston to 60°C. |

| q | Remove and install by using the Puller and Fitter - VW 222A-. |

| 4 - | Piston pin retaining ring |

| q | Replace. |

| 5 - | Connecting rod |

| q | With broken cap. |

| q | Only replace by complete set. |

| q | Mark correspondence with cylinder -B-. |

| q | Installation position: marks -A- point towards pulley side. |

| 6 - | Bearing shell |

| q | Pay attention to the assembly position. |

| q | Place bearing shells centered. |

| q | Do not invert bearing shells already used if they are going to be used again. |

| q | Check firm seating. |

| q | New axial clearance: 0.05...00.31 mm. Wear limit: 0.37 mm |

| q | Measure radial clearance with “Plastigage”: new: 0.01...00.05 mm. Wear limit: 0.09 mm. Do not rotate the crankshaft when measuring radial gap. |

| 7 - | Engine block |

| q | Check cylinder diameter → Fig. |

| q | Measures of the pistons and cylinders → Chapter. |

| 8 - | Connecting rod cap |

| q | Pay attention to the assembly position. |

| q | Due to splitting (breaking) of the connecting rods, the cap only seats in one position and fits only on the connecting rod to which it belongs. |

| 9 - | Oil injector |

| q | For piston cooling. |

| 10 - | Valve, 27 Nm |

| q | Opening pressure: 1.3...1.6 bar. |

| 11 - | 30 Nm 90° |

| q | Torx E 10. |

| q | Replace after each removal. |

| q | Lubricate the thread and supporting surface. |

| q | To measure the radial clearance, tighten to 30 Nm, without the angular torque. |

|

|

| Piston ring | Opening between ends | ||

| new | Wear limit | ||

| Compression rings | mm | 0,20...0,40 | 0,80 |

| Oil scraper ring | mm | 0,25...0,50 | 0,80 |

|

|

| Piston ring | Groove clearance | ||

| new | Wear limit | ||

| Compression rings | mm | 0,06...0,09 | 0,20 |

| Oil scraper ring | mm | 0,03...0,06 | 0,15 |

|

|

|

|

Note

Note

|

|

WARNING

WARNING