Polo Mk4

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

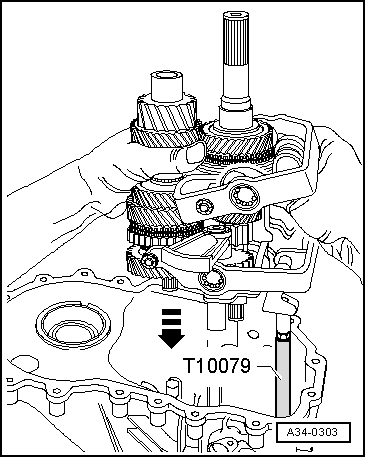

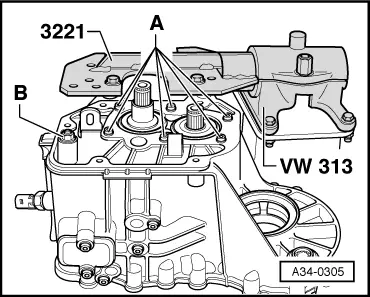

| Thickness (mm) | Replacement parts No. |

| 2,00 | -085 311 187- |

| 2,10 | -085 311 187 A- |

| 2,20 | -085 311 187 B- |

|

|

|