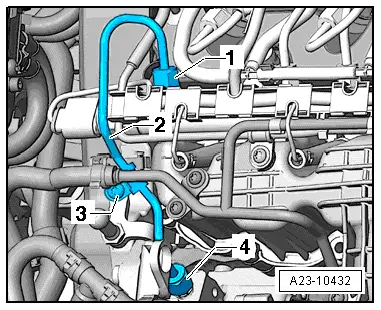

| Checking injectors with vacuum |

Note | t

| Leaky regulating valves in injectors may lead to irregular

engine running or may prevent engine from starting. |

| t

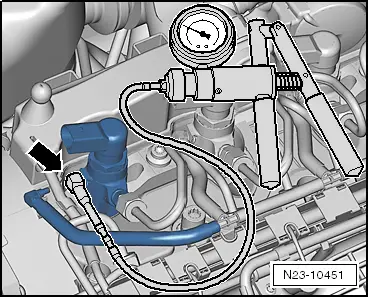

| To check regulating valves for soiling (and with it higher

leakage), further to the "classical" return quantity measurement,

checking with vacuum is also possible. |

| t

| Observe instructions for working on fuel system → Chapter. |

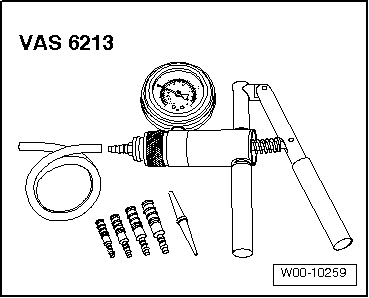

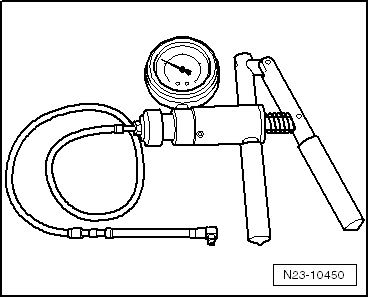

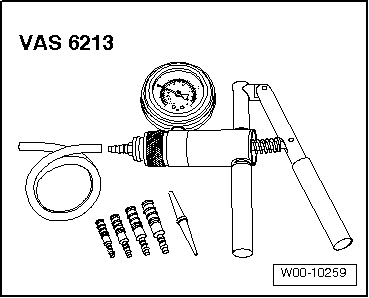

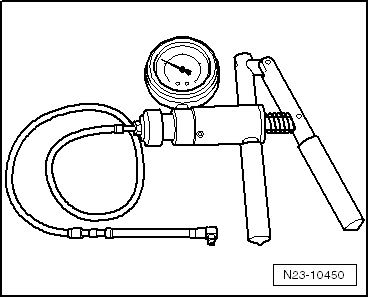

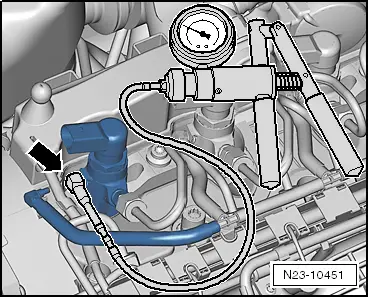

| Special tools and workshop equipment required |

|

|

|

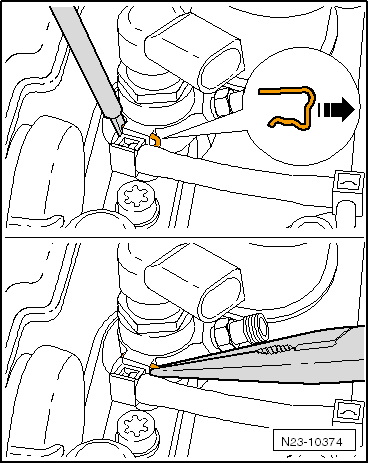

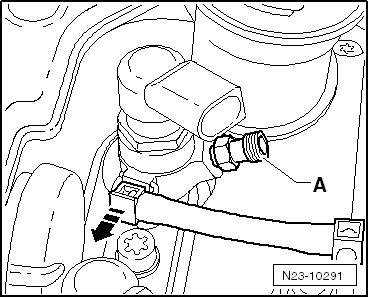

Note

Note

Note

Note