| –

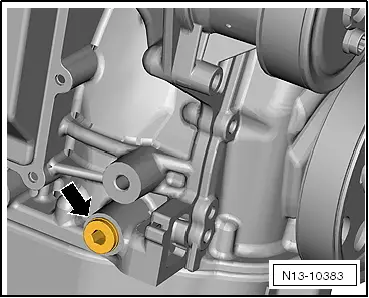

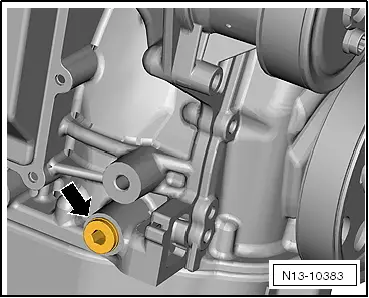

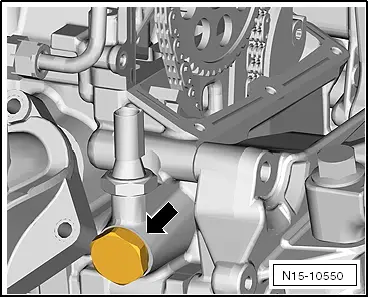

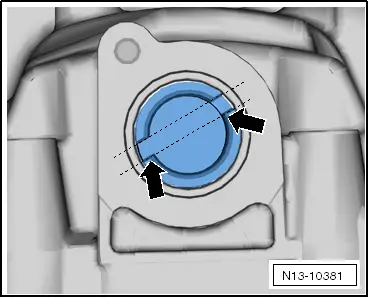

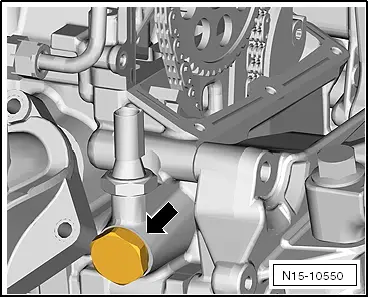

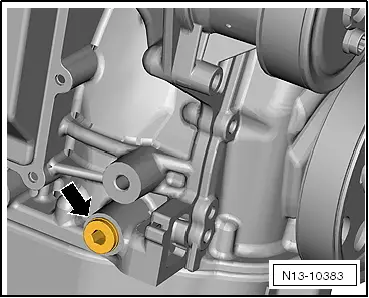

| Unscrew plug -arrow- from cylinder block. |

| –

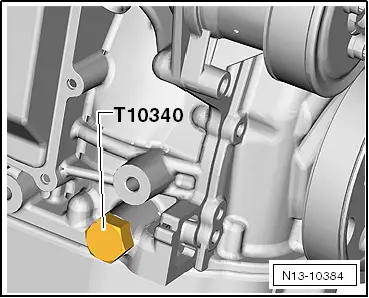

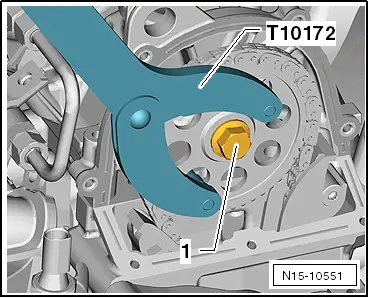

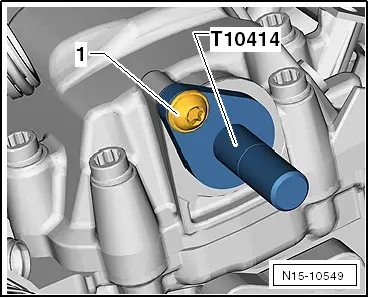

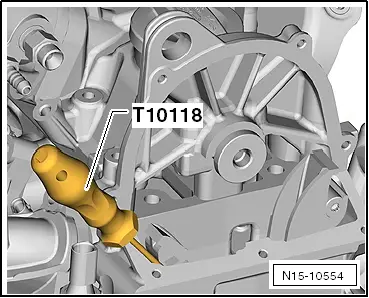

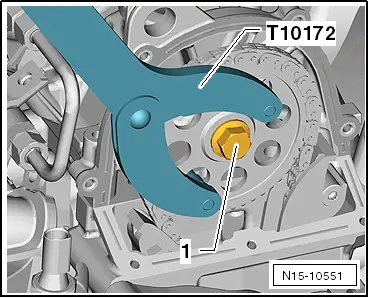

| Screw locking pin -T10340- to stop into crankcase. |

| –

| Turn crankshaft in normal direction of rotation until the stop. |

Caution | If locking pin -T10340- cannot be screwed in as far as stop, this indicates that crankshaft is not in the correct position! |

| In this case, proceed as described below. |

|

| –

| Turn crankshaft 1/4 revolution (90°) in normal direction of rotation. |

| –

| Screw locking pin -T10340- to stop into crankcase. |

| –

| Tighten locking pin -T10340- to 30 Nm. |

| –

| Turn crankshaft in normal direction of rotation until the stop. |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Caution

Caution