Polo Mk5

| Removing and installing bonded rubber bush |

| Special tools and workshop equipment required |

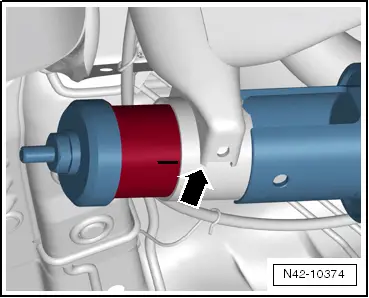

| t | Thrust piece -3416/1- |

| t | Thrust piece -3416/2- |

| t | Assembly tool -T10205- |

| t | Assembly tool -T10254- |

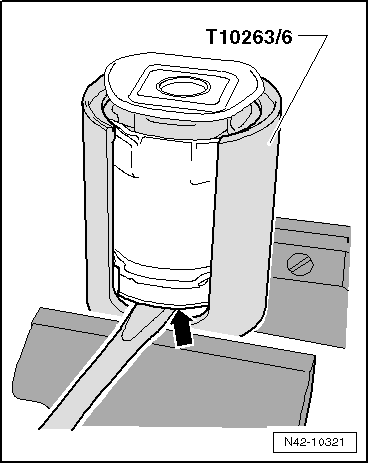

| t | Assembly tool -T10263- |

| t | Torque wrench -V.A.G 1332- |

| t | Engine and gearbox jack -V.A.G 1383 A- with universal gearbox support -V.A.G 1359/2- |

| t | Brake pedal depressor -V.A.G 1869/2- |

| t | Hydraulic press -VAS 6178- |

| t | Foot pump -VAS 6179- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

| Specified torques |

| Component | Specified torque | ||||

Rear axle to mounting bracket

| 45 Nm + 90° | ||||

| Rear left vehicle level sender -G76- to axle body | 15 Nm | ||||

| Retainer for left brake line | 20 Nm | ||||

| Brake lines to brake hose | 14 Nm |