| Possible deviation from specification | Possible cause of fault | Rectifying fault |

| l

| High pressure increases only slightly above the pressure measured when the engine is stopped, |

| l

| Low pressure falls only slightly, |

| l

| The required cooling output is not delivered. |

| | t

| Actuation of air conditioner compressor regulating valve -N280- is defective. |

| t

| The air conditioner compressor is defective. |

| | –

| Check actuation of air conditioner compressor regulating valve -N280-. |

| –

| Rinse (clean) refrigerant circuit → Chapter. |

| –

| Renew air conditioner compressor. |

|

| l

| High pressure rises above specification, |

| l

| Low pressure falls only slightly, |

| l

| The required cooling output is not delivered. |

| | t

| Restriction or obstruction in the refrigerant circuit. |

| | –

| Feel the refrigerant circuit with the hand to sense the temperature gradient. |

| l

| At one component a temperature gradient will be detected: |

| –

| If a hose or pipe is kinked or crushed, renew it. |

| –

| In case of an obstruction, blow through refrigerant circuit with compressed air and nitrogen. |

| l

| If no faults are found: |

| –

| Rinse (clean) refrigerant circuit → Chapter. |

|

| l

| High pressure and low pressure are normal at first, but after a while, the high pressure increases beyond the specification, |

| l

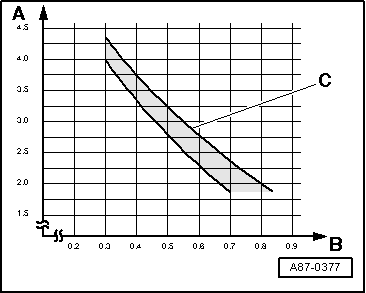

| The low pressure falls to the diagram value or lower, |

| l

| The cooling power called for is not delivered. |

| | t

| Moisture in the refrigerant circuit. |

| | –

| Blow through refrigerant circuit with compressed air and nitrogen. |

| –

| Repeat the check; if the system does not operate correctly |

| –

| Rinse (clean) refrigerant circuit → Chapter. |

| –

| Recharge refrigerant circuit. |

|

| l

| High pressure is normal, |

| l

| Low pressure is too low (see diagram), |

| l

| The cooling power required is delivered. |

| | t

| Actuation of air conditioner compressor regulating valve -N280- is defective. |

| t

| The air conditioner compressor is defective. |

| | –

| Check actuation of air conditioner compressor regulating valve -N280-. |

| –

| Rinse (clean) refrigerant circuit → Chapter. |

| –

| Renew air conditioner compressor. |

|

Note

Note

Note

Note Note

Note Note

Note