Up!

| Assembly overview - clutch |

Note

Note| t | Renew clutch plates and pressure plates with damaged or loose rivet connections. |

| t | Renew pressure plate and clutch plate together only. |

| t | Select clutch plate and pressure plate according to engine code and → Electronic Parts Catalogue (ETKA). |

| t | Clean input shaft splines and, on used clutch plate, hub splines. Remove corrosion and apply only a very thin coat of clutch plate spline grease -G 000 100- to splines. Then move clutch plate to and fro on input shaft until hub moves freely on shaft. Remove excessive grease. |

| t | Pressure plates are protected against corrosion and greased. Clean contact surface only. Otherwise, the service life of the clutch will be considerably reduced. |

| t | Pressure plate contact surface and clutch plate lining must make full contact with flywheel. Only then insert securing bolts. |

| t | The dowel sleeves for aligning engine and gearbox must be in cylinder block, install if necessary. |

| t | If dowel sleeves are not fitted, difficulties shifting gears, clutch problems and possible noises from the gearbox (rattling of gears which are not engaged) could occur. |

| 1 - | Flywheel |

| q | Removing and installing → Rep. gr.13. |

| q | Ensure that centring pins fit tightly |

| q | Keep contact surface for clutch lining free of grooves, oil and grease. |

| 2 - | Clutch plate |

| q | Allocation → Electronic parts catalogue (ETKA) |

| q | Installation position: spring cage faces pressure plate. |

| q | Centring → Fig. |

| q | Lightly grease splines |

Note

Note| Clean input shaft splines and, on used clutch plates, hub splines. Remove corrosion and apply only a very thin coat of grease -G 000 100- to input shaft splines. Then move clutch plate to and fro on input shaft until hub moves freely on shaft. Remove excessive grease. |

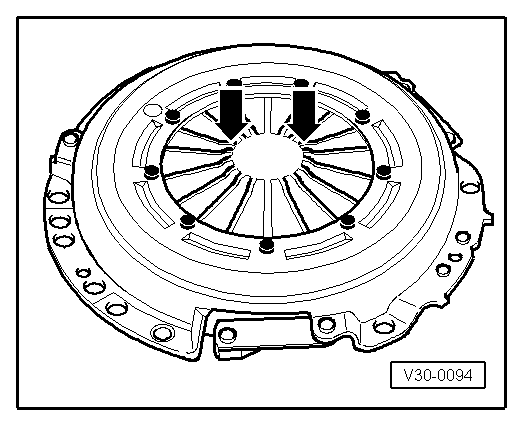

| 3 - | Pressure plate |

| q | Removing and installing → Chapter |

| q | Check ends of diaphragm spring → Fig. |

Note

Note| Pressure plates are protected against corrosion and greased. Clean contact surface only; otherwise the service life of the clutch will be considerably reduced. |

| 4 - | M6 bolt, 13 Nm, M7 bolt, 20 Nm |

| q | Determine according to → Electronic parts catalogue (ETKA). |

| q | Loosen or tighten diagonally and in steps |

|

|