Up!

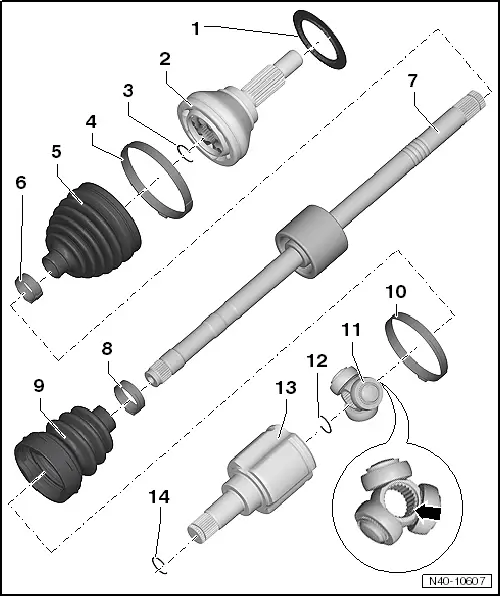

| Assembly overview - drive shaft |

| 1 - | Deflector ring |

| q | Ensure deflector ring is seated correctly before installing drive shaft → Anchor. |

| 2 - | Outer constant velocity joint |

| q | Renew only as complete unit |

| q | Removing → Anchor. |

| q | Installing: drive onto shaft with plastic hammer until compressed circlip seats |

| q | Checking → Chapter |

| 3 - | Retaining ring |

| q | Insert in groove in shaft |

| 4 - | Clamp |

| q | Always renew after removing. |

| q | Various versions |

| q | Allocation → Electronic parts catalogue „ETKA“ |

| q | Tightening → Fig. |

| 5 - | Boot for constant velocity joint |

| q | Check for splits and chafing |

| q | Material: Hytrel (polyester elastomer) |

| q | Coat sealing surface of constant velocity joint with -D 454 300 A2- before installing. |

| 6 - | Clamp |

| q | Always renew after removing. |

| q | Tightening → Fig. |

| 7 - | Drive shaft |

| 8 - | Clamp |

| q | Always renew after removing. |

| q | Tightening → Fig. |

| 9 - | Boot for triple roller joint |

| q | Check for splits and chafing |

| 10 - | Clamp |

| q | Always renew after removing. |

| q | Tightening → Fig. |

| 11 - | Triple roller star with rollers |

| The chamfer -arrow- points towards drive shaft splines. |

| 12 - | Retaining ring |

| q | Always renew after removing. |

| 13 - | Joint body |

| 14 - | Retaining ring |

| q | Insert in groove in joint body. |