| Carry out the following work: |

| –

| Lift vehicle far enough to take weight off front axle. |

| –

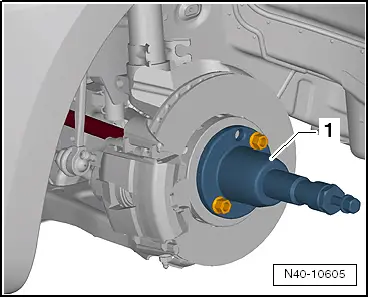

| Loosen twelve-point nut for drive shaft. |

Caution | Wheel bearings must not be subjected to load after bolt securing drive shaft to wheel hub has been loosened. |

| If wheel bearings are loaded with weight of vehicle, wheel bearings will be damaged and service life of wheel bearings will be considerably reduced. |

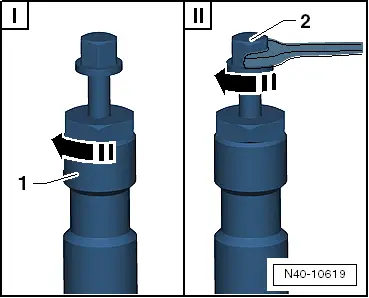

| It is not permissible to turn drive shaft bolt more than 90° anti-clockwise if vehicle is standing on its wheels. |

| Do not attempt to move the vehicle without the drive shafts fitted as this would damage the wheel bearing. If a vehicle nevertheless has to be moved, comply with the following: |

| t

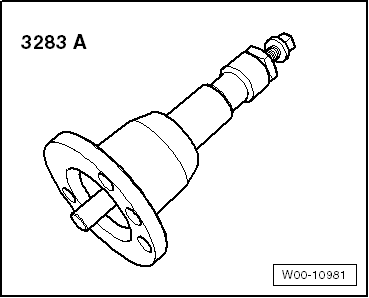

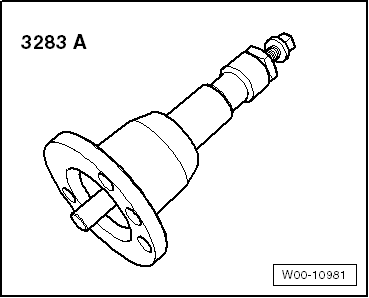

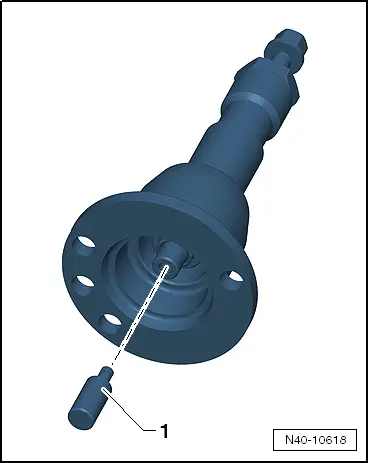

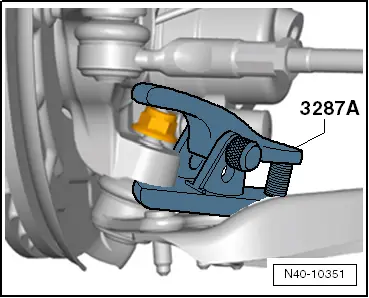

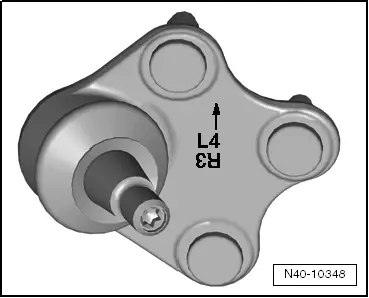

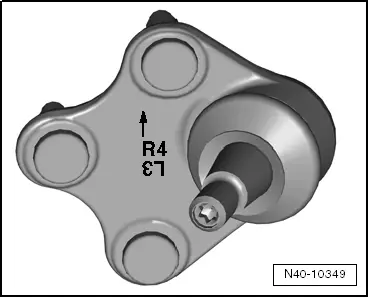

| Install an outer joint instead of the drive shaft. |

| t

| Tighten outer joint to 120 Nm. |

|

|

|

|

Note

Note Note

Note

Note

Note Note

Note

Note

Note

Caution

Caution