Up!

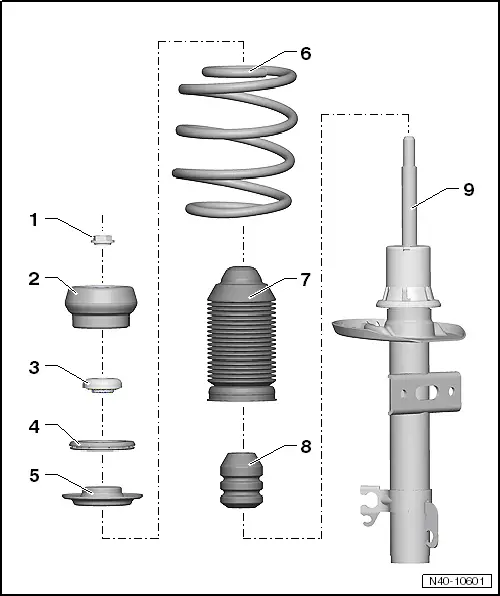

| Repairing suspension strut |

| 1 - | Nut |

| q | 60 Nm |

| q | Self-locking |

| q | Always renew after removing. |

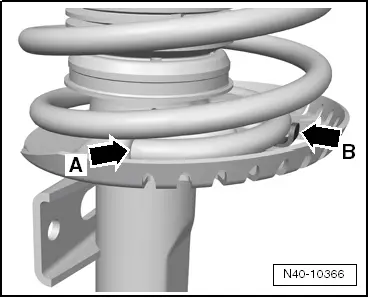

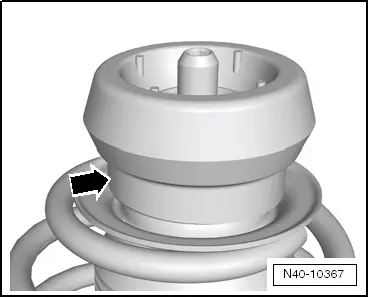

| 2 - | Suspension strut mounting |

| q | Note correct installation position → Anchor |

| 3 - | Deep groove ball thrust bearing |

| 4 - | Spacer |

| q | Allocation → Electronic parts catalogue „ETKA“ |

| 5 - | Spring plate |

| 6 - | Spring |

| q | Removing and installing → Chapter. |

| q | Observe colour coding |

| q | Allocation → Electronic parts catalogue „ETKA“ |

| The springs can be allocated by means of the PR number. The PR number is indicated on the vehicle data sticker. |

| q | Surface of coil must not be damaged. |

| 7 - | Protective sleeve |

| 8 - | Bump stop |

| 9 - | Shock absorber |

| q | Can be renewed separately |

| q | Allocation → Electronic parts catalogue „ETKA“ |

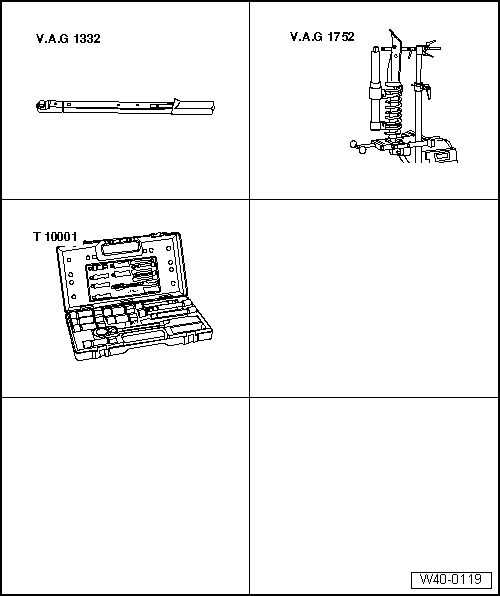

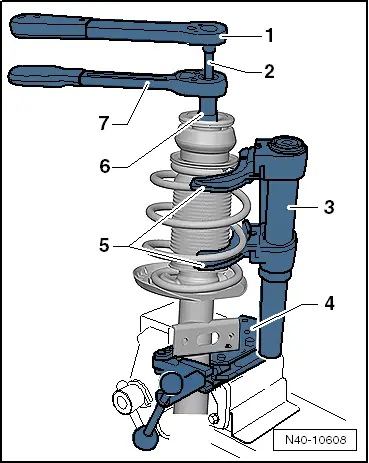

| Special tools and workshop equipment required |

| t | Torque wrench -V.A.G 1332- |

| t | Suspension strut clamp -V.A.G 1752- |

| t | Spring tensioner -V.A.G 1752/1- |

| t | Spring retainer -V.A.G 1752/7- |

| t | Shock absorber set -T10001- |

|

|

|

|

|

|

|

|

|

|

|

| Specified torque |

| Component | Specified torque | ||

Hexagon nut to piston rod

| 60 Nm |

WARNING

WARNING