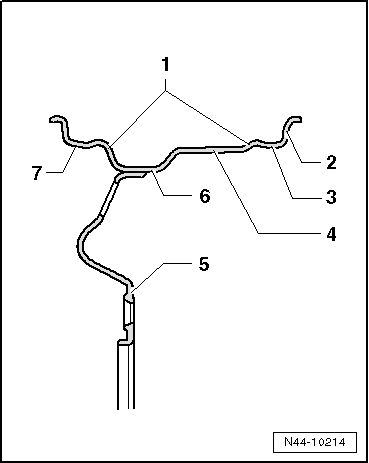

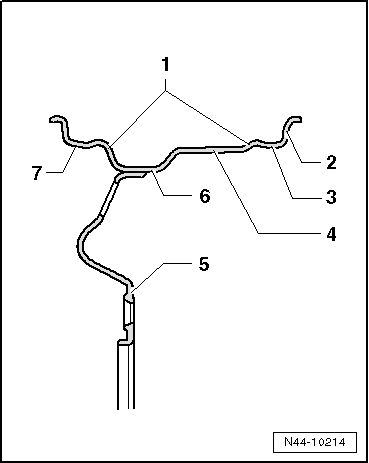

| Modern radial tyres for passenger cars are mounted only on safety rims. Safety rims have a hump -1- running along the bead seat. |

| 1 - | Hump (double hump H 2), extended double hump (EH2) |

| 3 - | Inner rim shoulder (e.g. tapered rim shoulder) |

| 7 - | Outer rim shoulder (e.g. tapered rim shoulder) |

| The hump prevents the tyre from being pressed out of the rim shoulder during travel with insufficient tyre pressure. |

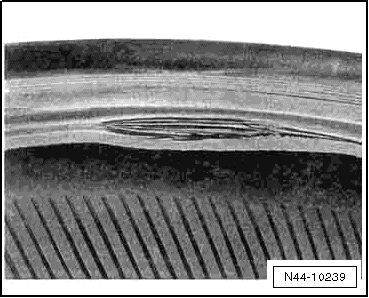

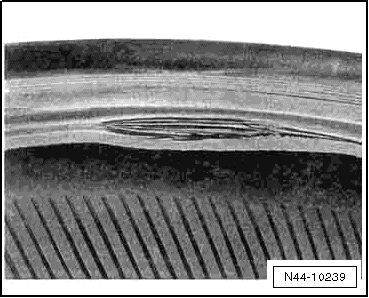

| When the tyre is inflated, the bead of the tyre may not slip completely over the outer rim hump. |

| In this case, there is a danger of the bead core becoming overstretched if the tyre pressure is too high. The steel wires would then rupture partially or completely. A broken bead core cannot be detected from the outside. |

| Special requirements for tyres with run-flat properties |

| Wheel rims with a raised double hump (Extended Hump EH2) are prescribed for tyres with run-flat properties (reinforced side walls) → Chapter. The raised double hump prevents the deflated tyre from slipping off its seat on the wheel rim when the tyre is run deflated. |

Note

WARNING | t

| Tyres with damaged bead cores are not seated safely and securely on the rim. Such tyres are a safety risk! |

| t

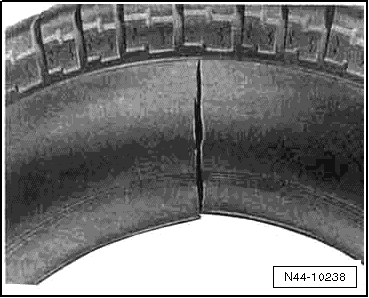

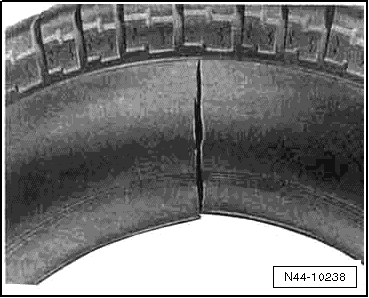

| In addition, there is a risk of the partly broken bead core breaking apart during continued operation and the tyre could suddenly tear open. If the bead core breaks during inflation, the carcass will also be destroyed. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note