| –

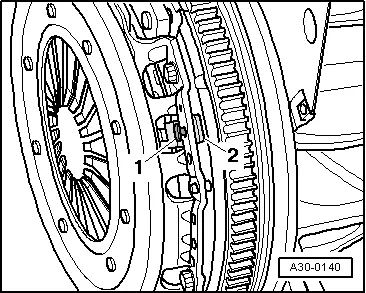

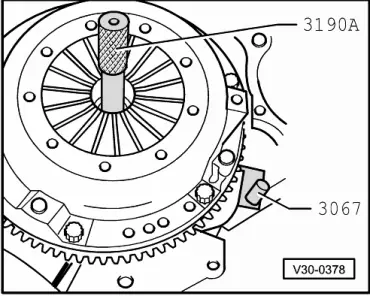

| Consecutively slacken off all 6 bolts in clockwise direction in 90° stages until the clutch pressure plate is released. |

| l

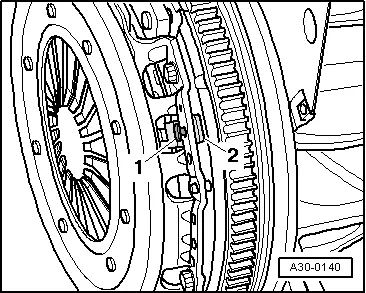

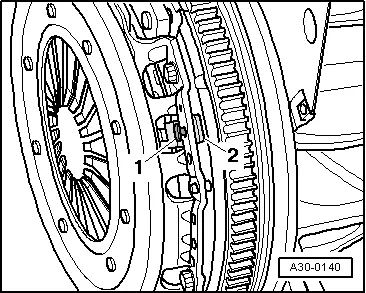

| Stop -2- with pin -1- should come loose when the bolts are slackened. |

| l

| If the stop does not come loose, push the pin towards the dual-mass flywheel. |

| –

| Take off clutch pressure plate and clutch plate. |

| Installation is carried out in reverse sequence; note the following: |

Note | t

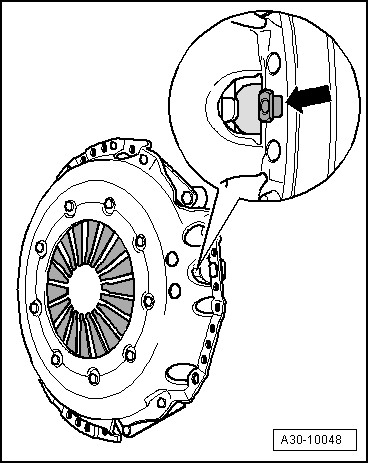

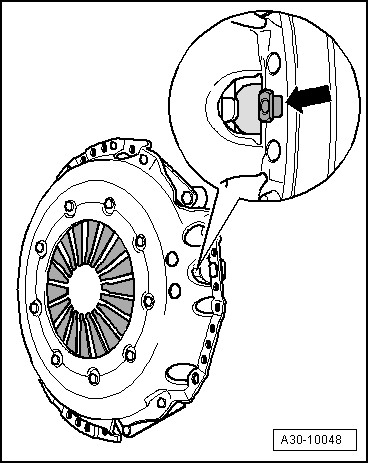

| Clutch plate linings must make full contact with flywheel and friction surface of pressure plate before securing bolts are inserted. |

| t

| Check that dowel sleeves for centralising engine/gearbox are in the cylinder block; install if necessary. |

| t

| If the dowel sleeves are not fitted, this will lead to gear-change problems, clutch malfunction and in some cases gearbox noise (gears will make rattling noises). |

|

|

|

Note

Note

Note

Note