A1

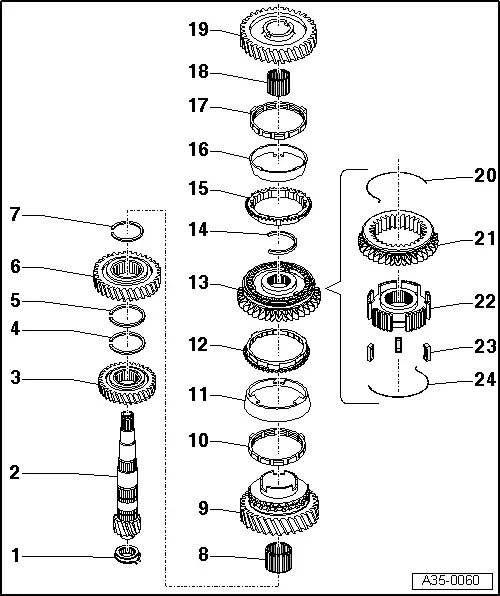

| Exploded view - output shaft |

Note

Note| t | Refer to → Electronics parts catalogue and technical data when installing new gear wheels or a new output shaft. |

| t | Pressing input and output shaft out of bearing mounting and grooved ball bearings → Chapter |

| t | Lubricate all bearings, selector gears and synchro-rings on output shaft with gear oil before installing. |

| t | Do not interchange synchro-rings. When re-using synchro-rings, always fit on the same selector gear. |

| 1 - | Roller bearing |

| q | With circlip |

| q | Removing and installing → Chapter |

| q | Installation position: the circlip in the bearing faces the output shaft |

| 2 - | Output shaft |

| q | With inner race for roller bearing (depending on version) |

| q | Inner race cannot be removed from output shaft |

| q | Check bearing seat / bearing inner race for scoring or other damage |

| q | If you detect scoring or other damage to the bearing seat / inner race, renew both output shaft and roller bearing |

| 3 - | 4th gear wheel |

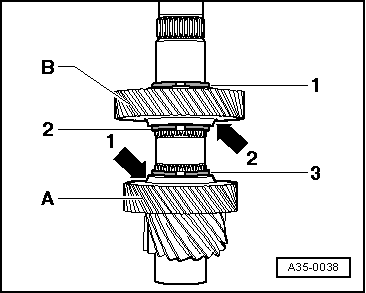

| q | Installation position: Collar faces 3rd gear → Fig. |

| q | Removing and installing → Chapter |

| 4 - | Circlip |

| 5 - | Circlip |

| 6 - | 3rd gear wheel |

| q | Installation position: Collar faces 4th gear → Fig. |

| q | Removing and installing → Chapter |

| 7 - | Circlip |

| 8 - | Needle bearing |

| q | For 2nd gear |

| 9 - | 2nd speed selector gear |

| 10 - | Inner ring for 2nd gear |

| q | Removing and installing → Chapter |

| q | Checking for wear → |

| 11 - | Outer ring for 2nd gear |

| q | Removing and installing → Chapter |

| q | Renew if scored or if there are visible traces of wear |

| 12 - | 2nd gear synchro-ring |

| q | Removing and installing → Chapter |

| q | Checking for wear → |

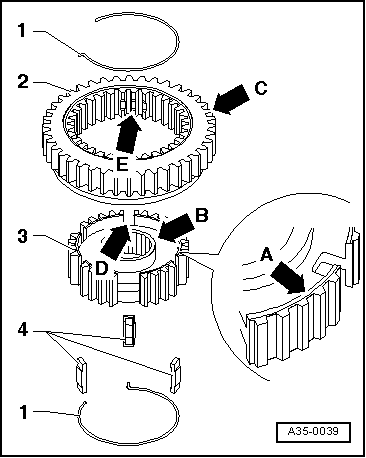

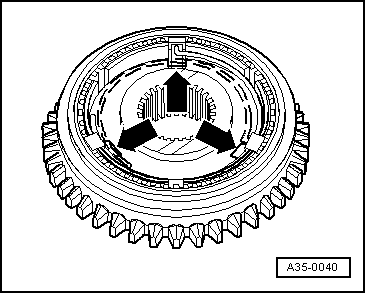

| 13 - | Locking collar with synchronising hub for 1st and 2nd gear |

| q | Removing and installing → Chapter |

| q | Dismantling and assembling → Fig. |

| 14 - | Circlip |

| 15 - | 1st gear synchro-ring |

| q | Removing and installing → Chapter |

| q | Checking for wear → |

| 16 - | Outer ring for 1st gear |

| q | Removing and installing → Chapter |

| q | Renew if scored or if there are visible traces of wear |

| 17 - | Inner ring for 1st gear |

| q | Removing and installing → Chapter |

| q | Checking for wear → |

| q | Check lugs for scoring |

| 18 - | Needle bearing |

| q | For 1st gear |

| 19 - | 1st speed selector gear |

| q | Removing and installing → Chapter |

| 20 - | Spring |

| q | Installation position → Fig. |

| 21 - | Locking collar for 1st and 2nd gear |

| q | Dismantling and assembling → Fig. |

| 22 - | Synchronising hub for 1st and 2nd gear |

| q | Dismantling and assembling → Fig. |

| 23 - | Locking pieces |

| q | 3x |

| 24 - | Spring |

| q | Installation position → Fig. |

|

|

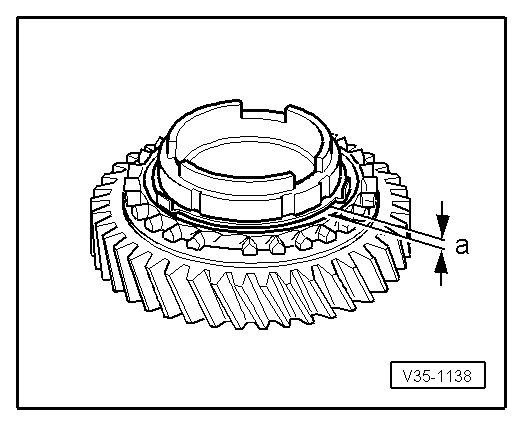

| Gap -a- | Installation depth | Wear limit |

| 1st and 2nd gear | 0.75 ... 1.25 mm | 0.3 mm |

|

|

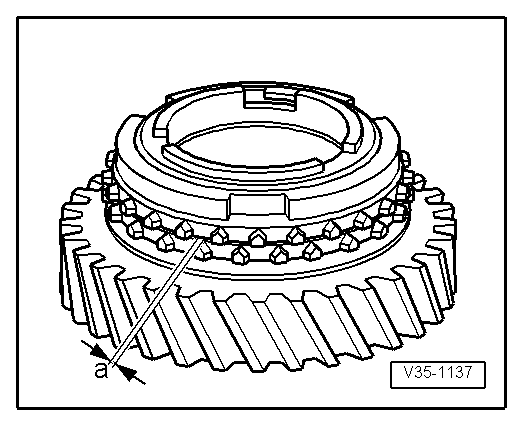

| Gap -a- | Installation depth | Wear limit |

| 1st and 2nd gear | 1.2 ... 1.8 mm | 0.5 mm |

|

|

|

|