| t

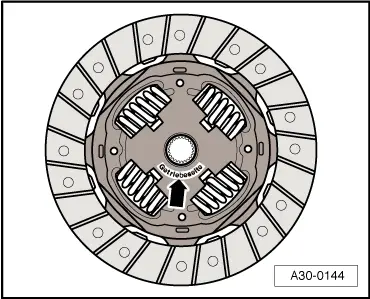

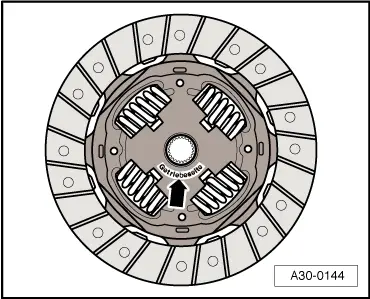

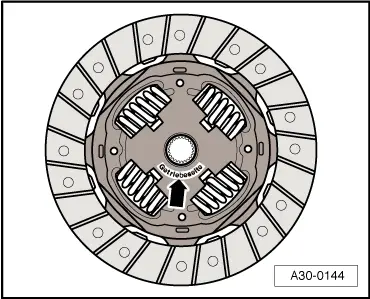

| Installation position of clutch plate: protruding spring cage / marking „Getriebeseite“ (gearbox side), if provided, faces towards pressure plate. |

| t

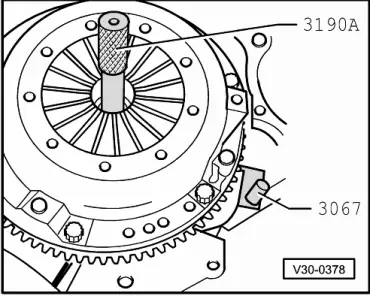

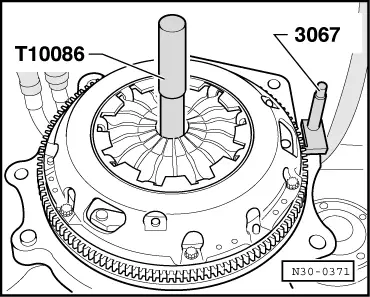

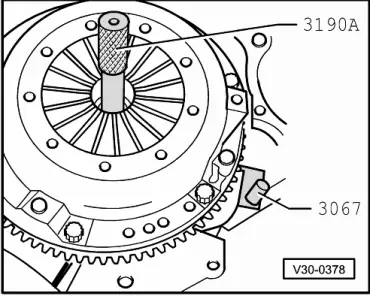

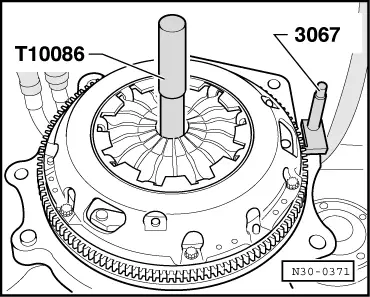

| Clutch pressure plate friction surface and clutch plate lining must make full contact with flywheel. Only then insert bolts. |

| t

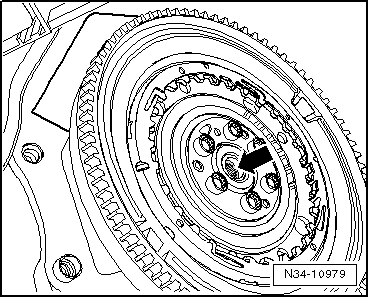

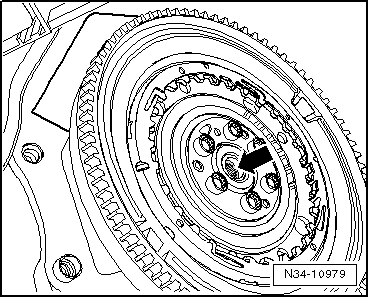

| Check that dowel sleeves for centralising engine/gearbox are in the cylinder block; install if necessary. |

| t

| If the dowel sleeves are not fitted, this will lead to gear-change problems, clutch malfunction and in some cases gearbox noise (gears will make rattling noises). |

|

|

|

Note

Note

Note

Note