A1

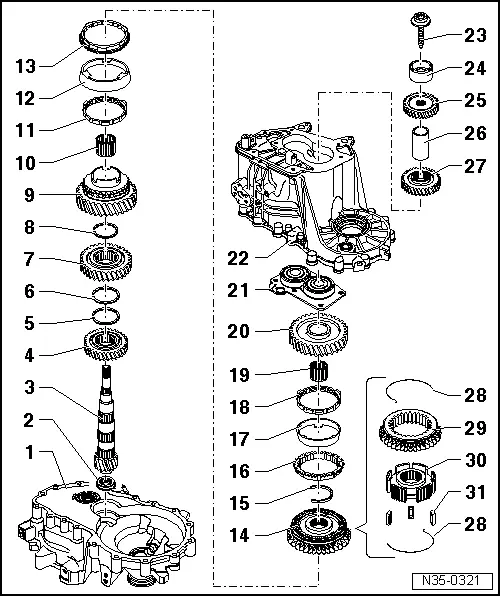

| Exploded view - output shaft |

Note

Note| t | Securing gearbox to assembly stand → Chapter |

| t | When fitting new gear wheels or output shaft refer to technical data → Chapter and → Electronic parts catalogue. |

| t | Lubricate all bearings, selector gears and synchro-rings on output shaft with gear oil before installing. |

| t | Do not interchange synchro-rings. When re-using synchro-rings, always fit on the same selector gear. |

| 1 - | Clutch housing |

| q | Servicing → Chapter |

| 2 - | Roller bearing |

| q | With circlip |

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| q | Installation position: the circlip in the bearing faces the output shaft |

| 3 - | Output shaft |

| q | With inner race for roller bearing (depending on version) |

| q | Inner race cannot be removed from output shaft |

| q | Check bearing seat / bearing inner race for scoring or other damage |

| q | If you detect scoring or other damage to the bearing seat / inner race, renew both output shaft and roller bearing |

| 4 - | 4th gear wheel |

| q | Installation position: Collar faces 3rd gear → Fig. |

| 5 - | Circlip |

| q | Renew |

| 6 - | Circlip |

| q | Renew |

| 7 - | 3rd gear wheel |

| q | Installation position: Collar faces 4th gear → Fig. |

| 8 - | Circlip |

| q | Renew |

| 9 - | 2nd speed selector gear |

| 10 - | Needle bearing |

| q | For 2nd gear |

| 11 - | Inner ring for 2nd gear |

| q | Checking for wear → Fig. |

| q | Installation position → Fig. |

| 12 - | Outer ring for 2nd gear |

| q | Fit on inner ring → Item. |

| q | Renew if scored or if there are visible traces of wear |

| q | Installation position → Fig. |

| 13 - | 2nd gear synchro-ring |

| q | Checking for wear → Fig. |

| q | Installation position → Fig. |

| 14 - | Locking collar with synchronising hub for 1st and 2nd gear |

| q | Press off together with 2nd speed selector gear after removing circlip → Item → Fig. |

| q | Dismantling → Fig. |

| q | Assembling locking collar/synchronising hub → Fig. and → Fig. |

| q | Installation position → Fig. |

| q | Pressing on → Fig. |

| 15 - | Circlip |

| q | Pressing out → Fig. |

| q | Fitting → Fig. |

| 16 - | 1st gear synchro-ring |

| q | Checking for wear → Fig. |

| q | Assemble so that the recesses engage on the locking pieces on the locking collar → Item |

| 17 - | Outer ring for 1st gear |

| q | Insert in synchro-ring → Item |

| q | Installation position |

| q | Renew if scored or if there are visible traces of wear |

| 18 - | Inner ring for 1st gear |

| q | Checking for wear → Fig. |

| q | Check lugs for scoring |

| q | Installation position → Fig. |

| 19 - | Needle bearing |

| q | For 1st gear |

| 20 - | 1st speed selector gear |

| q | Installation position → Fig. |

| 21 - | Bearing mounting with grooved ball bearings |

| q | If bearing mounting is separated from gearbox housing, it must always be renewed |

| q | Pressing off without 5th gear wheel → Fig. |

| q | Pressing off with 5th gear wheel → Fig. |

| q | Pressing on → Fig. |

| 22 - | Gearbox housing |

| q | Servicing → Chapter |

| 23 - | Bolt |

| q | Removing and installing → Chapter |

| 24 - | Roller bearing inner race |

| q | Mark before removing |

| q | Do not interchange with roller bearing inner race for input shaft |

| q | Removing and installing → Chapter |

| 25 - | 6th gear wheel |

| q | Installation position: collar faces 5th gear wheel |

| q | Removing and installing → Chapter |

| 26 - | Sleeve |

| q | Removing and installing → Chapter |

| 27 - | 5th gear wheel |

| q | Installation position: collar faces 6th gear wheel |

| q | Removing and installing → Chapter |

| 28 - | Spring |

| q | Installation position → Fig. |

| 29 - | Locking collar |

| 30 - | Synchronising hub |

| 31 - | Locking pieces |

| q | 3x |