| –

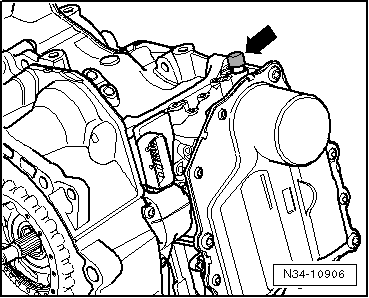

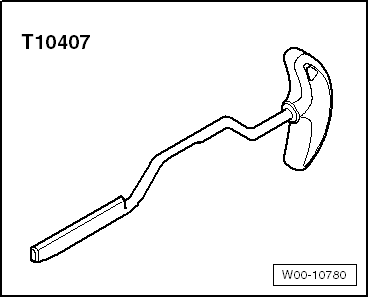

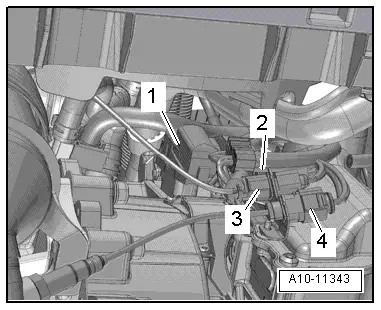

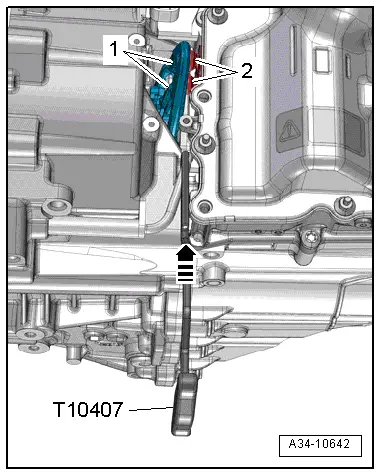

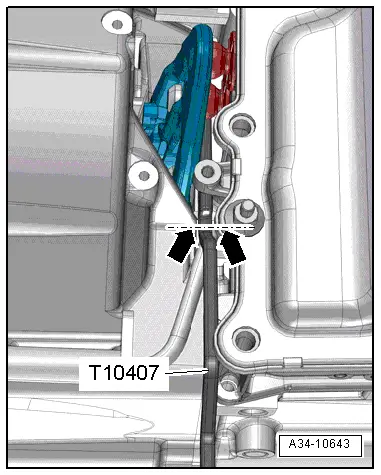

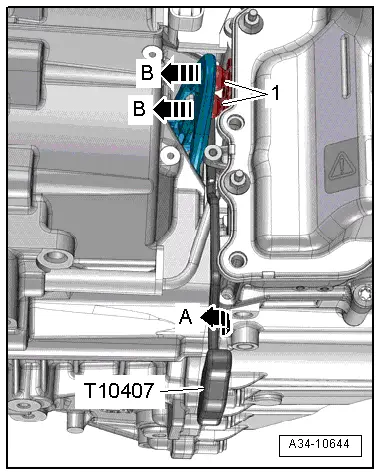

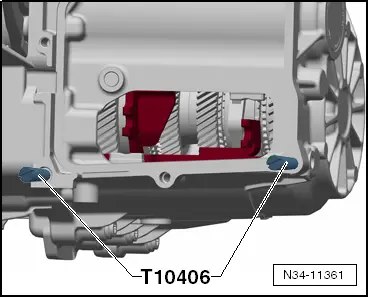

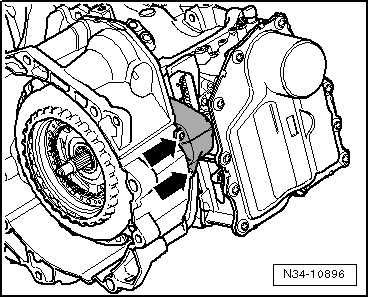

| If necessary, press the assembly lever -T10407- against the gearbox housing with a screwdriver to prevent it from slipping out when it is turned. |

Note | t

| The assembly lever -T10407- remains inserted between the engaging levers and the gearbox housing while removing and installing the mechatronic unit. |

| t

| If necessary, press the assembly lever -T10407- against the gearbox housing. |

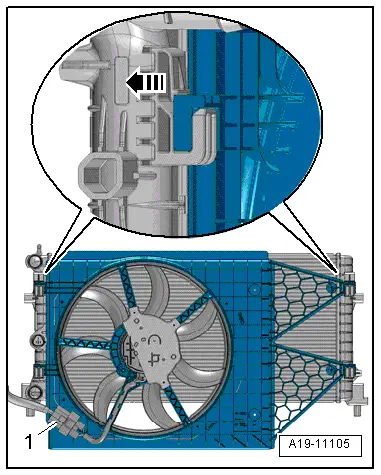

Caution | Risk of irreparable damage to gearbox components. |

| t

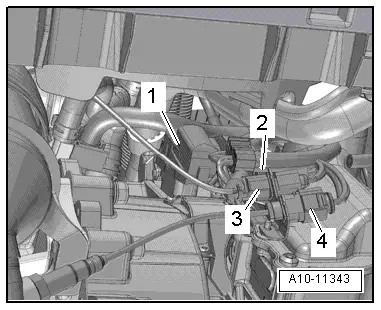

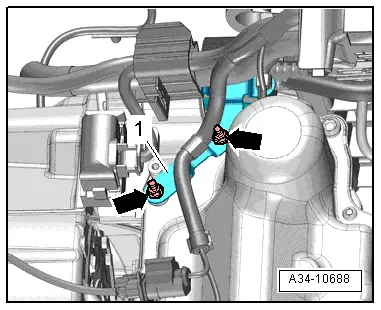

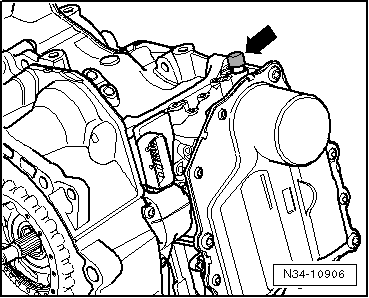

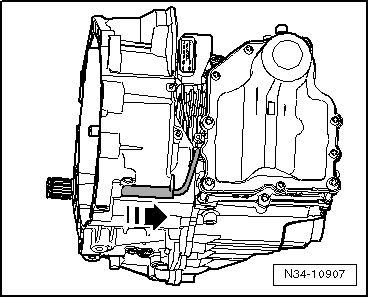

| Before touching or removing the mechatronic unit for dual clutch gearbox -J743-, always discharge any static electricity by touching an earthed object with your hand. |

| t

| Never touch the contacts in the gearbox connector with your hands. Electrostatic discharge could cause irreparable damage to the control unit and, consequently, the mechatronic unit. |

|

| –

| Touch a suitable earthed object with your hand (without gloves) to discharge any static electricity. |

Note | Make sure that the screwdriver used to support the assembly lever -T10407- does not jam against the mechatronic unit. |

Caution | Risk of damage to mechatronic unit for dual clutch gearbox -J743-! |

| t

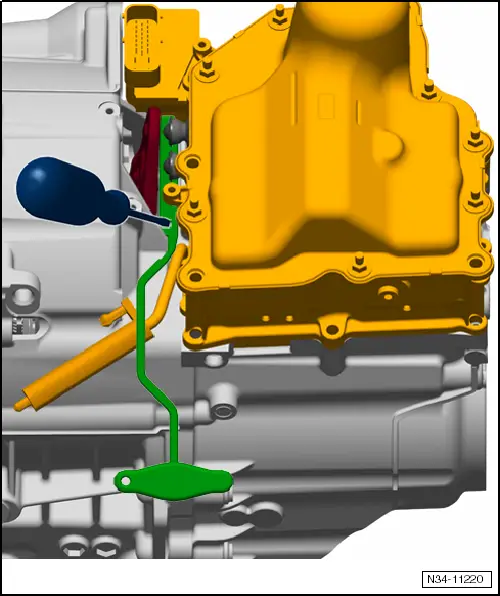

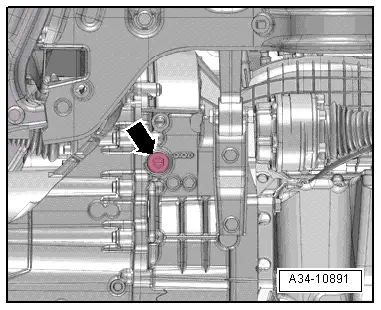

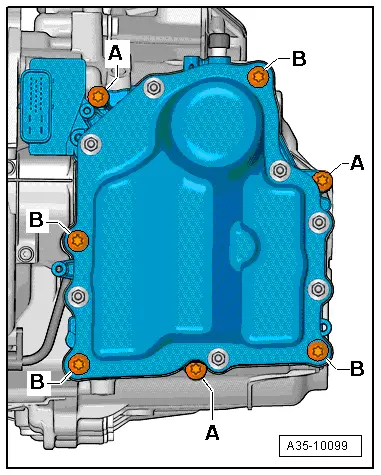

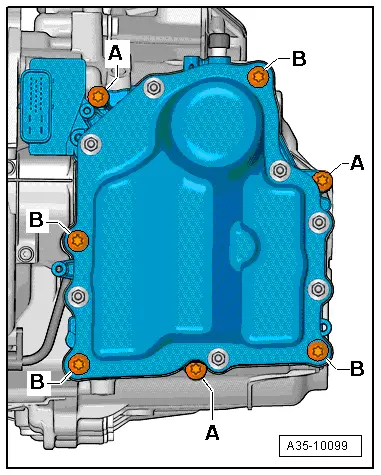

| Do not loosen bolts securing cover on mechatronic unit for dual clutch gearbox -J743-. |

| t

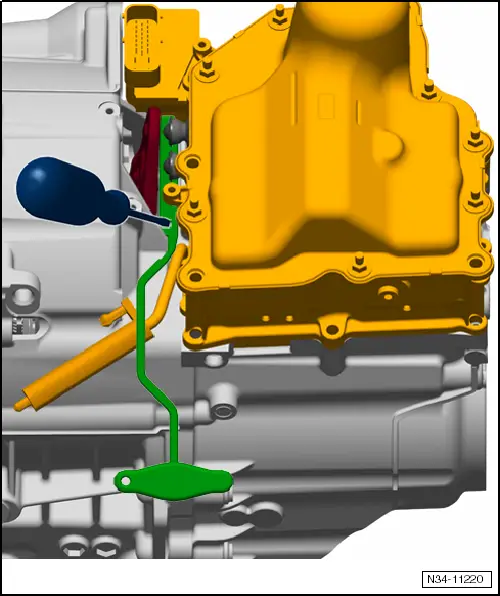

| Make sure that no oil escapes through the breather hole when placing down mechatronic unit for dual clutch gearbox -J743- after removal. |

| t

| Oil that has escaped cannot be refilled! |

|

Note | The mechatronic unit is returned for reconditioning complete with oil filling. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution

Note

Note