A1

| Cylinder head - exploded view |

| 1 - | Cylinder head |

| q | Removing and installing → Chapter |

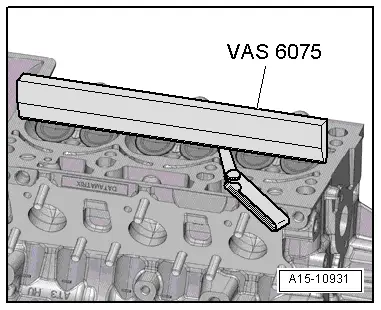

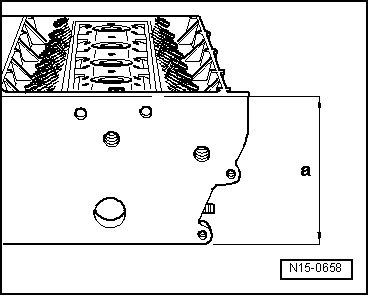

| q | Checking for distortion → Fig. |

| q | Sealing surface for camshaft housing must be free of oil and grease |

| q | If renewed, change coolant and engine oil |

| 2 - | Guide pin |

| q | Tightening torque → Item |

| 3 - | Bolt |

| q | 20 Nm |

| 4 - | Engine lifting eye |

| 5 - | Hydraulic valve compensation element |

| q | Do not interchange |

| q | Lubricate running surfaces with oil |

| 6 - | Securing clip |

| q | Check for firm attachment |

| q | Not supplied separately |

| 7 - | Roller rocker finger |

| q | Check roller bearings for ease of movement |

| q | Lubricate contact surfaces before installing |

| q | Attach to hydraulic compensation element -item 5- using securing clip -item 6- |

| 8 - | Oil strainer |

| q | Inserted into cylinder head |

| q | Renew |

| 9 - | Seal |

| q | Inserted into cylinder head |

| q | 4x |

| q | Renew |

| 10 - | Camshaft housing |

| q | Removing and installing → Chapter |

| 11 - | Bolt |

| q | Renew |

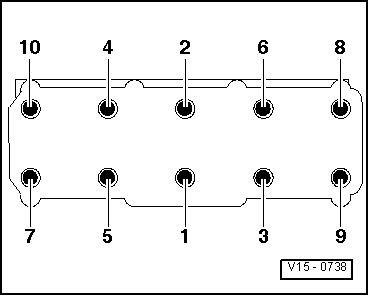

| q | Note correct sequence when loosening → Anchor |

| q | Tightening torque and sequence → Fig. |

| 12 - | Bolt |

| q | 20 Nm |

| 13 - | Engine lifting eye |

| 14 - | Bolt |

| q | Renew |

| q | Note correct sequence when loosening → Anchor |

| q | Tightening torque and sequence → Fig. |

| 15 - | Cylinder head gasket |

| q | Renewing → Chapter „Removing and installing cylinder head“ |

| q | Installation position: Part number points towards cylinder head, and must be legible from the inlet side |

| q | If renewed, change coolant and engine oil |

|

|

|

|

Note

Note

|

|

| Stage | Bolts | Tightening torque/angle specification |

| 1. | -1 … 10- | Screw in bolts by hand until they make contact |

| 2. | -1 … 10- | 20 Nm |

| 3. | -1 … 10- | turn 90° further |

| 4. | -1 … 10- | turn 90° further |