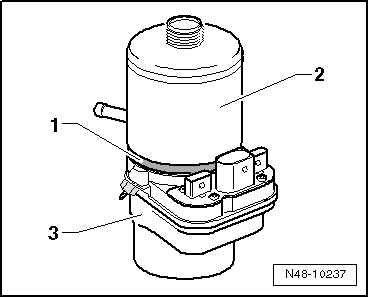

| Renewing reservoir for motor/pump unit |

Note | t

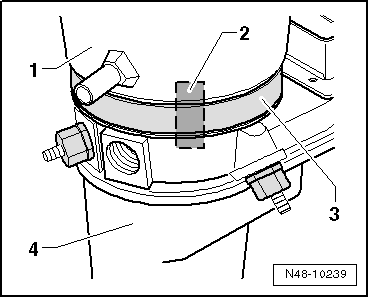

| It is important to keep all parts clean when renewing the reservoir. |

| t

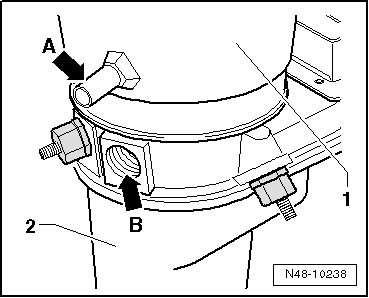

| Before separating connections, thoroughly clean entire circumference between return line connection on reservoir and pressure line connection on motor/pump unit. Do not use aggressive cleaning agents such as brake cleaner, petrol, thinner or the like. |

| t

| Place removed parts on a clean surface and cover them up. |

| t

| If repairs cannot be completed immediately, carefully cover open components. |

| t

| Do not use fluffy cloths. |

| t

| Only remove replacement parts from packaging immediately prior to installation. |

| t

| Only use genuine spare parts from original packaging. |

| t

| The contact surface between the reservoir and motor/pump unit must not come into contact with sealants. |

| Special tools and workshop equipment required |

| t

| Hot air blower, e.g. -V.A.G 1416- |

| t

| Protective gloves (commercially available) |

| t

| Rubber head hammer (commercially available) |

| Residual amounts of fluid will remain in the motor/pump unit after the hydraulic fluid is extracted. |

| –

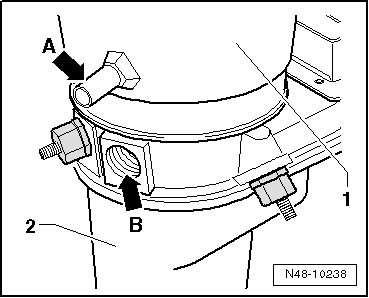

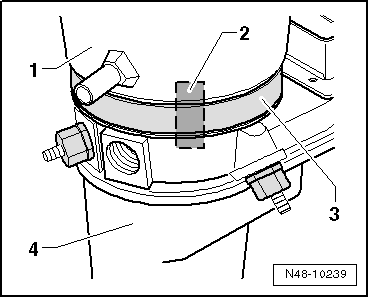

| Seal off threaded union for pressure line on motor/pump unit. |

| –

| Remove bracket from motor/pump unit. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note