| t

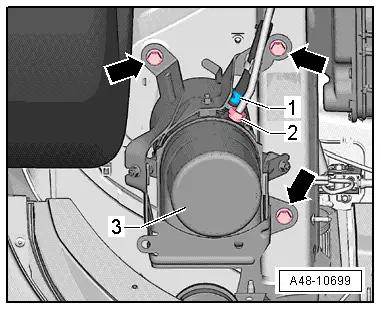

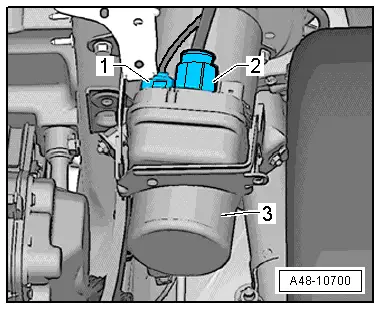

| Repairs must not be performed on the motor/pump unit |

| t

| If problems are reported, determine the cause by means of a function test, pressure test, leakage test and „Guided Fault Finding“. |

| t

| If a fault is found, the motor/pump unit must be renewed. |

| t

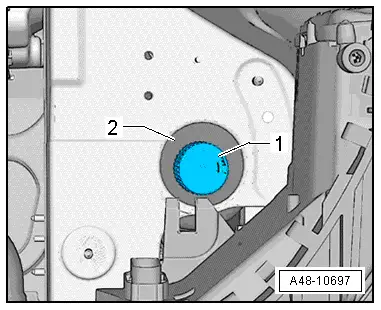

| Residual quantities of hydraulic fluid will remain in the motor/pump unit and in the return line and pressure line after the fluid has been drawn off. |

| t

| Do not re-use hydraulic fluid which has been drained off. |

| t

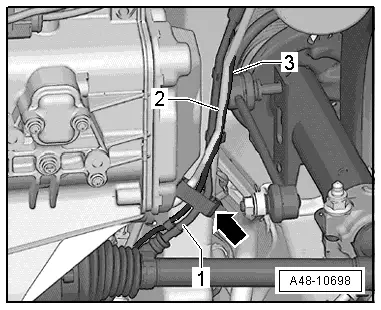

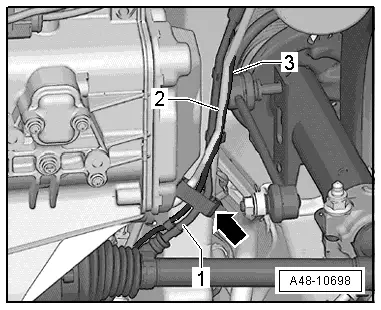

| The pressure line and return line must not be clamped off with hose clamps, e.g. -3094-, or other tools. Applying a clamp to these lines can cause damage. |

| t

| When bending or repositioning the pressure line or return line, make sure that the bending radius is not less than 100 mm to prevent damage to the lines. |

|

|

|