A2

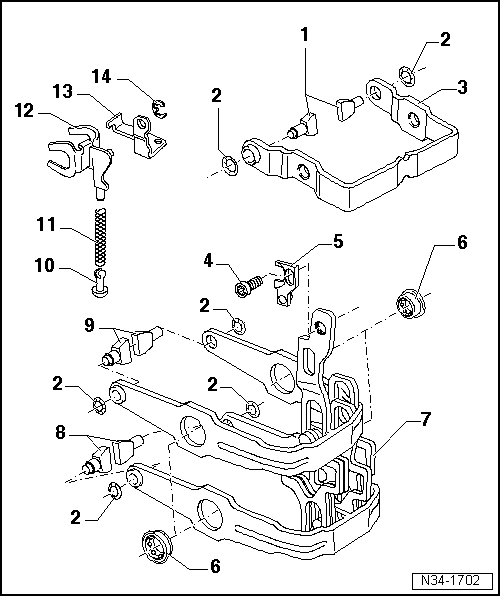

| Exploded view - dismantling and assembling selector forks |

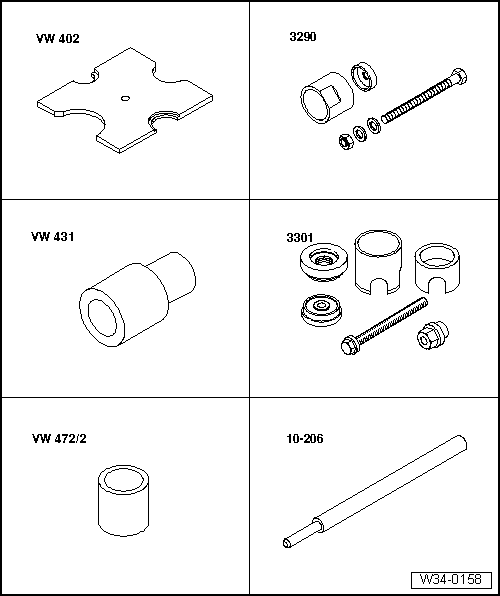

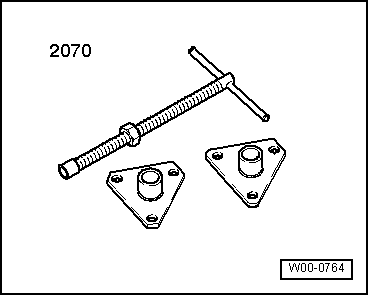

| Special tools and workshop equipment required |

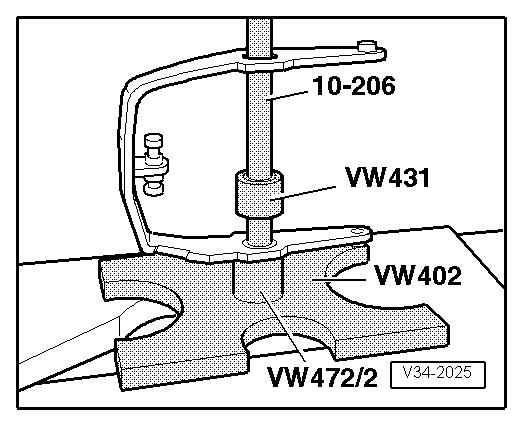

| t | Thrust plate -VW 402- |

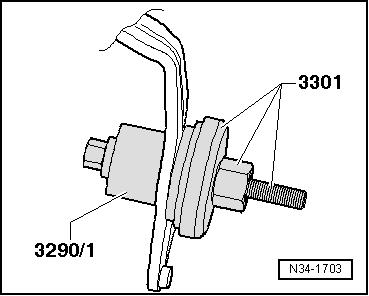

| t | Thrust piece -3290/1- of assembly tool -3290- |

| t | Assembly tool -3301- |

| t | Press tool -VW 431- |

| t | Spacer sleeve -VW 472/2- |

| t | Drift -10 - 206- |

|

|

|

|

|

|

|

|

Note

Note| The selector fork cluster ( → Item) does not have to be dismantled in order to remove and install detent segments, lock washers and angular contact ball bearings. |

| 1 - | 5th gear detent segment |

| q | Identification → Fig. |

| q | Detent segment should turn freely after lock washer is installed |

| 2 - | Lock washer |

| q | Always renew |

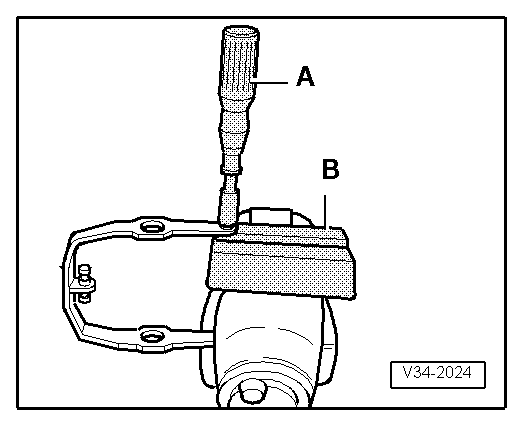

| q | Removing → Fig. |

| q | Installing → Fig. |

| 3 - | 5th gear selector fork |

| q | Adjusting → |

| 4 - | Bolt |

| q | 25 Nm |

| 5 - | 5th gear selector jaw |

| 6 - | Angular contact ball bearing |

| q | 4x |

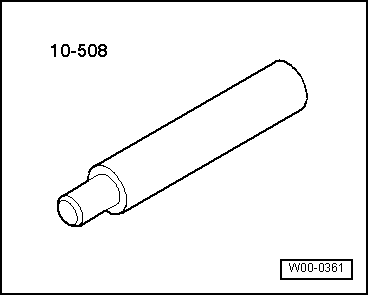

| q | Removing → Fig. |

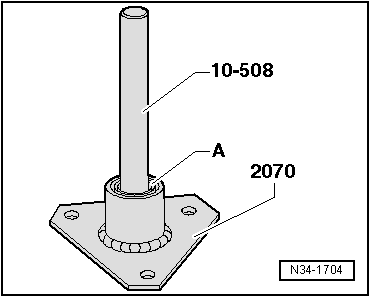

| q | Pressing inner race into outer race → Fig. |

| q | Installing → Fig. |

| 7 - | Selector fork cluster with selector plates |

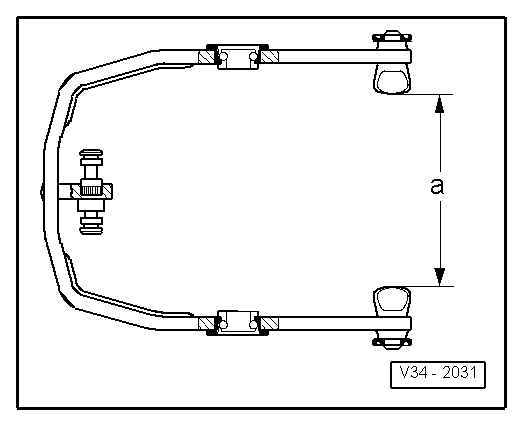

| q | Check selector fork with detent segments installed → Fig. |

| 8 - | 1st/2nd gear detent segment |

| q | Identification → Fig. |

| q | Detent segment should turn freely after lock washer is installed |

| 9 - | 3rd/4th gear detent segment |

| q | Identification → Fig. |

| q | Detent segment should turn freely after lock washer is installed |

| 10 - | Sliding piece |

| 11 - | Spring |

| 12 - | Reverse gear selector fork |

| 13 - | Support for reverse gear selector fork |

| 14 - | Circlip |

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

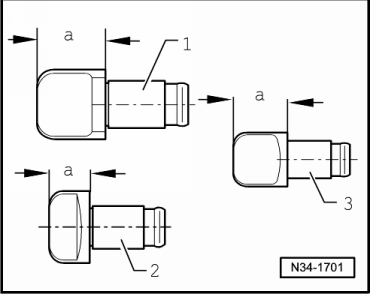

| Dimension -a- (mm) | |

| 1st/2nd gear selector fork | 87.2…87.9 |

| 1st/2nd gear selector fork in combination with modified synchromesh ( → Chapter) | 88.4…89.1 |

| 3rd/4th gear selector fork | 96.0…96.7 |

|