| –

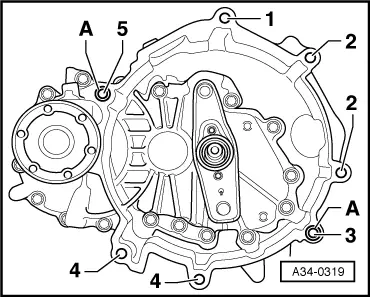

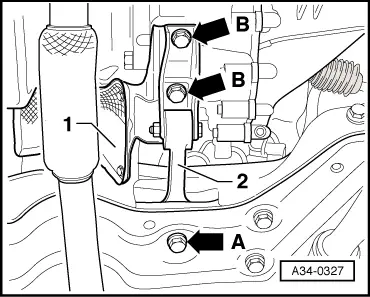

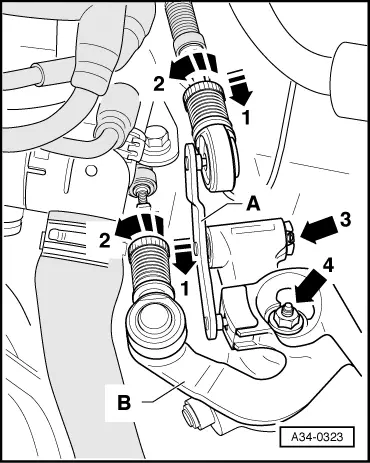

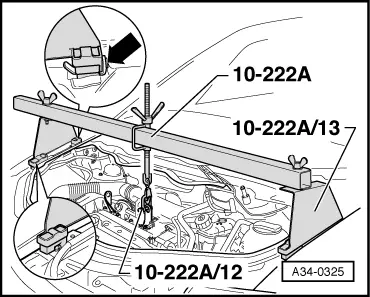

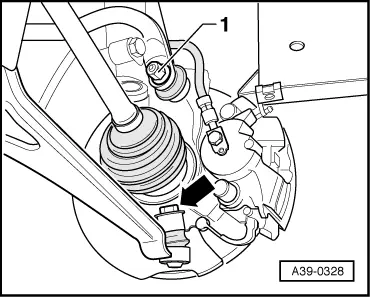

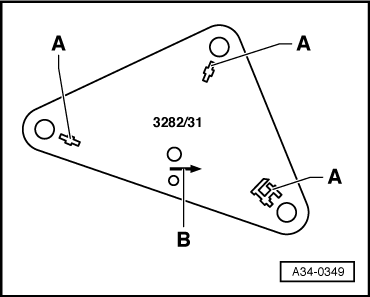

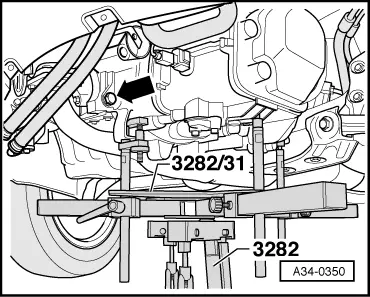

| Set support arm on sliding bracket by means of locking pin -arrow-. |

| Number of holes visible = 5 |

| –

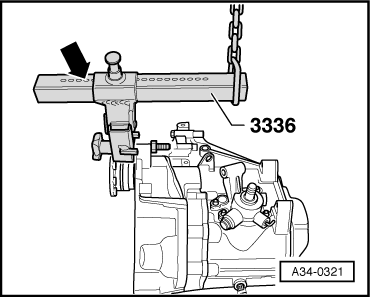

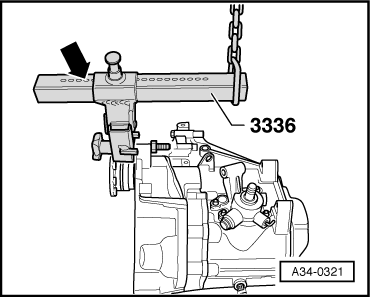

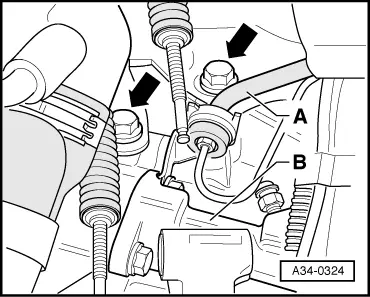

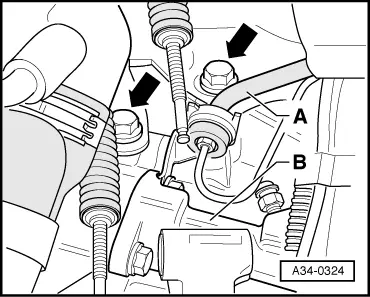

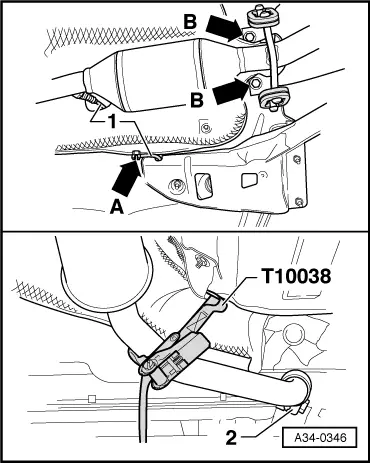

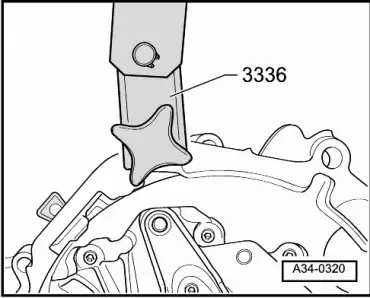

| Take up gearbox with workshop hoist and gearbox lifting tackle -3336-. |

| –

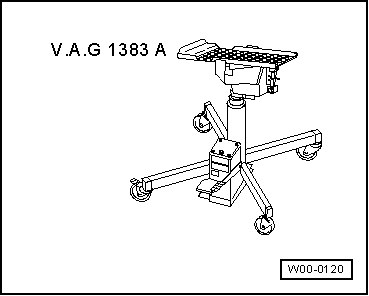

| Set down gearbox as required (for example in transport container). |

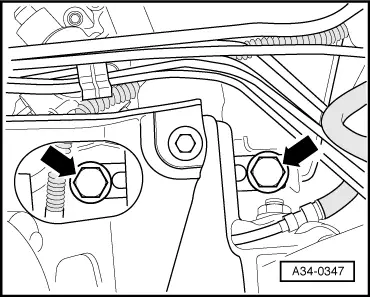

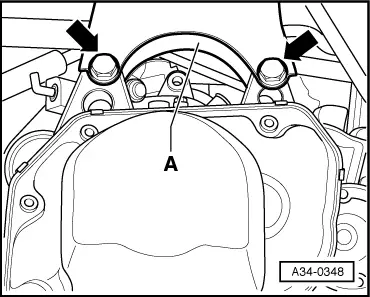

| Installation of gearbox is carried out in reverse order of removal. When installing gearbox, ensure that engine/gearbox mountings are free of stress → Rep. Gr.10. |

Note | t

| Clean splines of input shaft and apply a thin coat of grease for clutch plate splines -G 000 100-. |

| t

| When renewing gearbox, ensure that intermediate plate is correctly positioned. |

| t

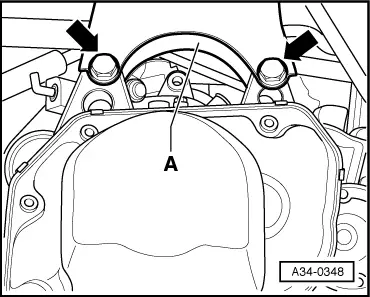

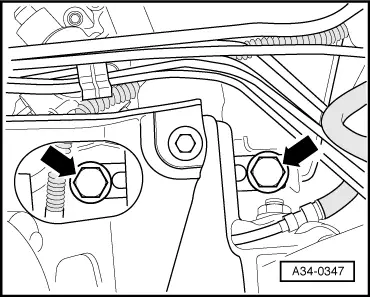

| Check that dowel sleeves for centralising engine/gearbox are in the cylinder block, install if necessary. |

| t

| Secure coupling rod to anti-roll bar and suspension link to wheel bearing housing → Rep. Gr.40. |

| t

| When the battery is reconnected, please remember to check and activate the vehicle equipment (radio, clock, convenience electrical systems etc.). |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note