A2

| Servicing gearbox housing and clutch housing |

| Special tools and workshop equipment required |

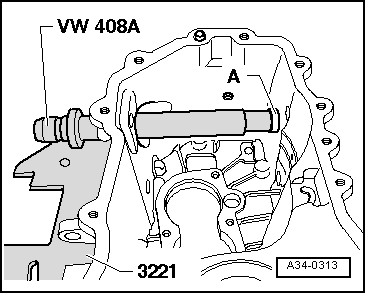

| t | Press tool -VW 408 A- |

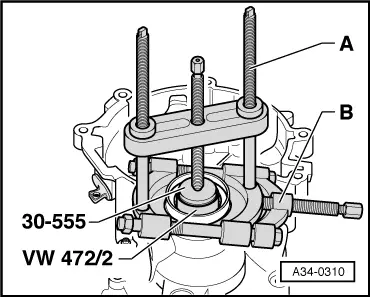

| t | Spacer sleeve -VW 472/2- |

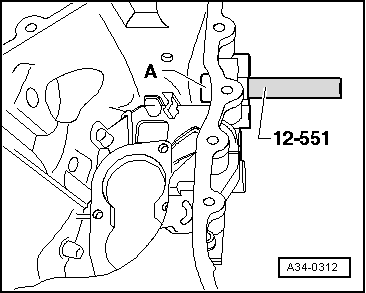

| t | Centring mandrel -12-551- |

| t | Press tool -30-555- |

| t | Assembly device -3066- |

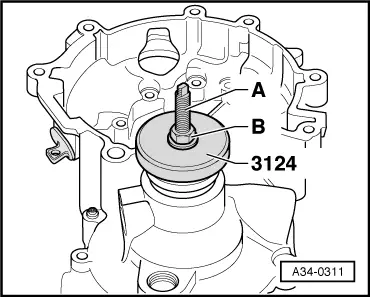

| t | Thrust piece -3124- |

| t | Gearbox support -3221- (modifying → Chapter) |

| t | Multi-point bit -3357- |

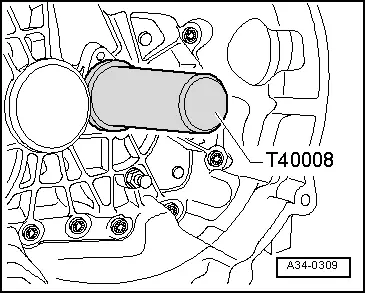

| t | Thrust piece -T40008- |

| t | Torque wrench -V.A.G 1331- |

| t | -2-puller, e.g. -Kukko 18/1- |

| t | -3-Splitter 12...75 mm, e.g. -Kukko 17/1- |

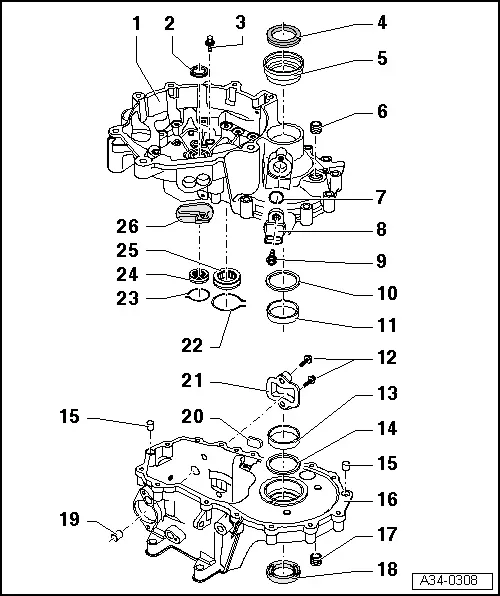

| 1 - | Clutch housing |

| q | If renewed: adjust differential → Chapter |

| 2 - | Input shaft oil seal |

| q | Lever out with screwdriver |

| q | Driving in → Fig. |

| 3 - | Ball head stud |

| q | 20 Nm |

| q | Lubricate with MoS2 grease |

| 4 - | Flange shaft oil seal (right-side) |

| q | Renewing with gearbox installed → Chapter |

| 5 - | Sleeve |

| q | For oil seal |

| q | Pulling out → Fig. |

| q | Drawing in → Fig. |

| 6 - | Oil filler plug |

| q | 25 Nm |

| q | Remove and install with multi-point bit XZN 12 -3357- |

| 7 - | O-ring |

| q | Not fitted on gearboxes with code letters GKT, GRZ and GSK |

| q | Allocate according to → Electronic parts catalogue |

| q | If fitted, always renew |

| 8 - | Speedometer sender -G22- |

| q | Not fitted on gearboxes with code letters GKT, GRZ and GSK |

| q | A plug is fitted instead of sender on gearboxes with gearbox code letters GKT, GRZ and GSK |

| q | Allocate according to → Electronic parts catalogue |

| 9 - | Bolt |

| q | 5 Nm and turn 90° further |

| q | Always renew |

| 10 - | Shim S2 |

| q | For differential |

| q | Determining thickness → Chapter |

| 11 - | Tapered roller bearing outer race |

| q | For differential |

| q | Pulling out and pressing in → Chapter |

| q | If renewed: adjust differential → Chapter |

| 12 - | Bolt |

| q | 5 Nm and turn 90° further |

| q | Always renew |

| 13 - | Tapered roller bearing outer race |

| q | For differential |

| q | Pulling out and pressing in → Chapter |

| q | If renewed: adjust differential → Chapter |

| 14 - | Shim S1 |

| q | For differential |

| q | Always 1 mm thick |

| 15 - | Dowel sleeve |

| q | 2x |

| 16 - | Gearbox housing |

| q | Modification from gearbox build date 10 06 2: enlarged bearing seat for tapered roller bearing/differential → Chapter |

| q | For correct version, refer to → Electronic parts catalogue |

| q | If renewed: adjust differential → Chapter |

| 17 - | Oil drain plug |

| q | 25 Nm |

| 18 - | Flange shaft oil seal (left-side) |

| q | Renewing with gearbox installed → Chapter |

| 19 - | Sleeve |

| q | For selector shaft |

| q | Driving out → Fig. |

| q | Driving in → Fig. |

| 20 - | Magnet |

| q | Held in place by joint surface of housing |

| 21 - | Cover plate |

| q | Before tightening apply sealant -AMV 188 200- to sealing surface |

| 22 - | Circlip |

| q | Fit in groove of roller bearing → Item |

| 23 - | Circlip |

| q | Fit in groove of roller bearing → Item |

| 24 - | Roller bearing |

| q | For input shaft |

| q | Removing and installing → Chapter |

| 25 - | Roller bearing |

| q | For output shaft |

| q | Removing and installing → Chapter |

| 26 - | Plug |

| q | Insert into bore of clutch housing |

|

|

|

|

|

|

|

|

Note

Note