A2

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

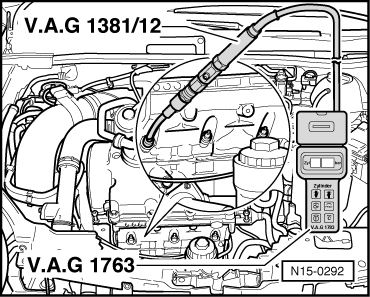

| Compression pressure | bar |

| When new | 25.0 … 31.0 |

| Wear limit | 19.0 |

| Difference between cylinders | 5.0 (maximum) |

|

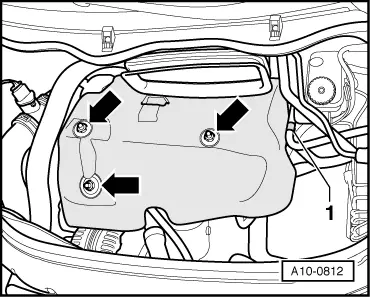

| Component | Nm |

| Engine cover panel to bracket | 5.5 |