A2

| Removing and installing cylinder head |

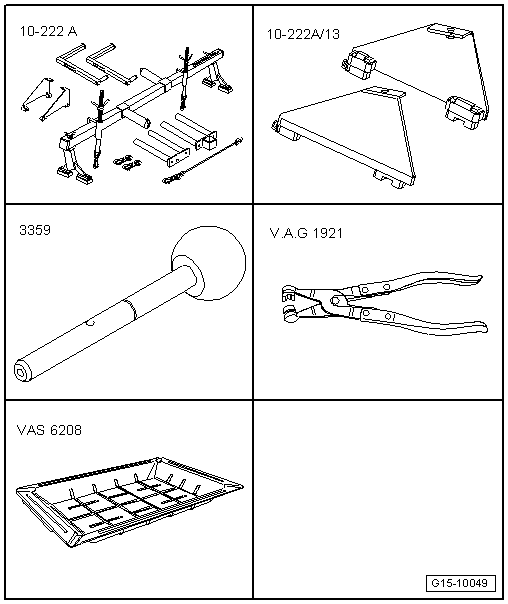

| Special tools and workshop equipment required |

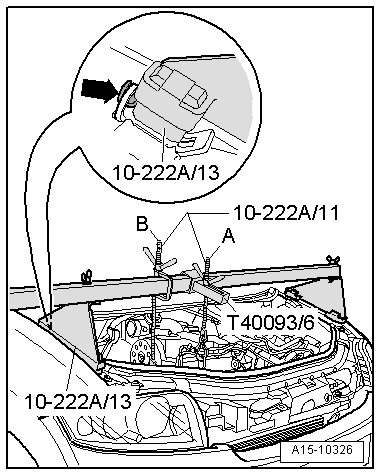

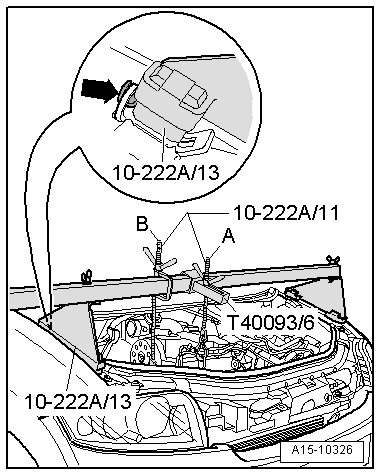

| t | Support bracket -10 - 222 A- |

| t | Adapter -10 - 222 A /13- |

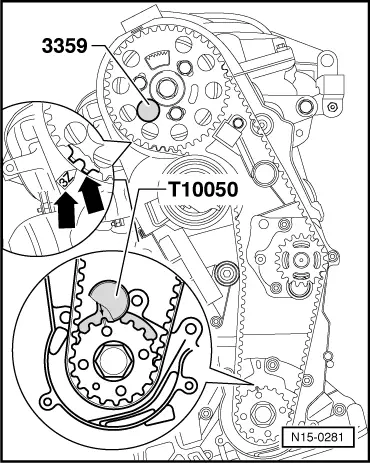

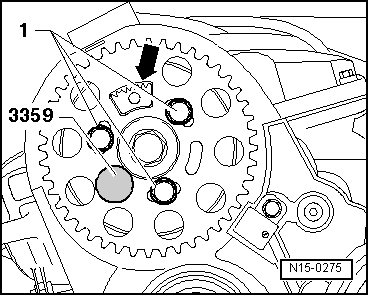

| t | Diesel injection pump locking pin -3359- |

| t | Hose clip pliers -V.A.G 1921- |

| t | Drip tray for workshop hoist -VAS 6208- |

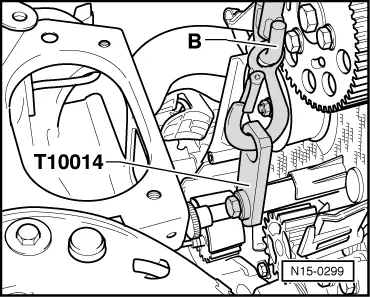

| t | Bracket -T10014- |

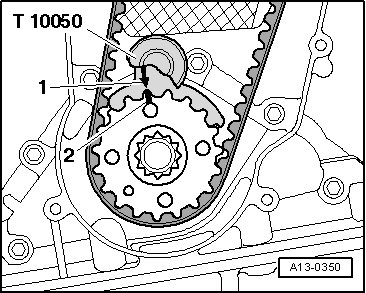

| t | Crankshaft stop -T10050- |

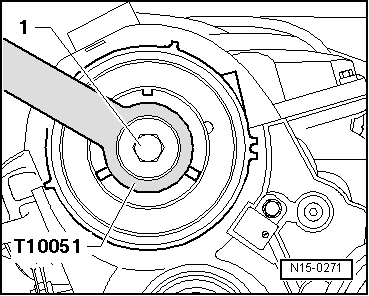

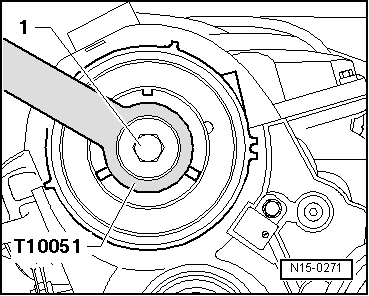

| t | Counterhold tool -T10051- |

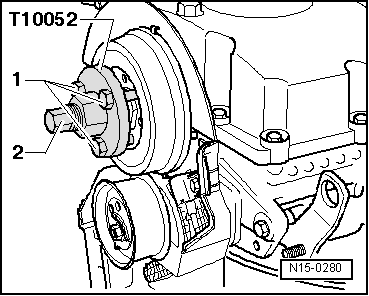

| t | Puller -T10052- |

| t | Adapter -T40093/6- from engine support bracket (supplementary set) -T40093- |

Note

Note

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

| Component | Nm | ||||

| Hall sender -G40- to cylinder head | 10 1) | ||||

| Rear toothed belt cover to cylinder head | M6 | 10 1) | |||

| M8 | 20 1) | ||||

| Stud to cylinder head | 15 | ||||

| Hub to camshaft | 100 | ||||

| Engine support to cylinder block | 45 | ||||

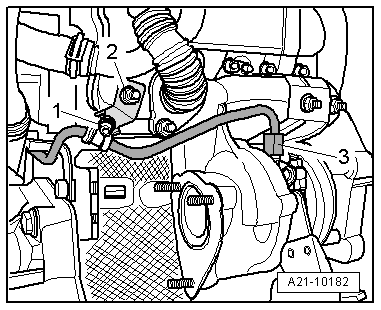

| Oil supply pipe to: | Oil filter bracket | 22 | |||

| Turbocharger | 22 | ||||

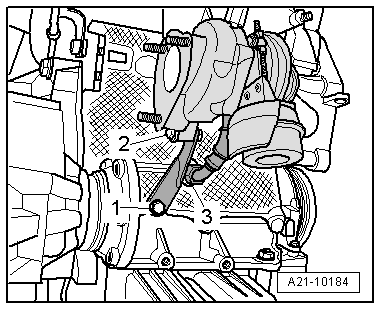

| Oil return pipe to: | Turbocharger | 15 | |||

| Cylinder block | 30 | ||||

| Support for turbocharger to: | Turbocharger | 20 | |||

| Cylinder block | 25 | ||||

| Bracket for wiring harness to coolant hose/pipe connection | 10 | ||||

| Bracket for oil supply pipe to coolant hose/pipe connection | 10 | ||||

| Air pipe to: | Turbocharger | 8 | |||

| Sump | 8 | ||||

| Drive shaft heat shield to cylinder block | 33 | ||||

| Engine cover panel to bracket | 5.5 | ||||

| |||||

Caution

Caution WARNING

WARNING