A2

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

Note

Note

|

|

|

|

|

|

Note

Note

|

|

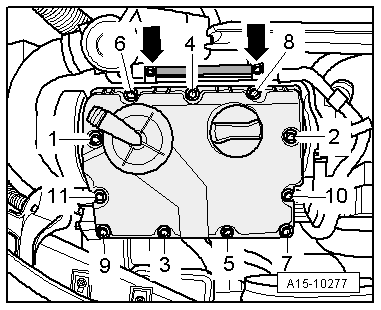

| Component | Nm |

| Cylinder head cover to cylinder head | 10 |

| Engine cover panel to bracket | 5.5 |