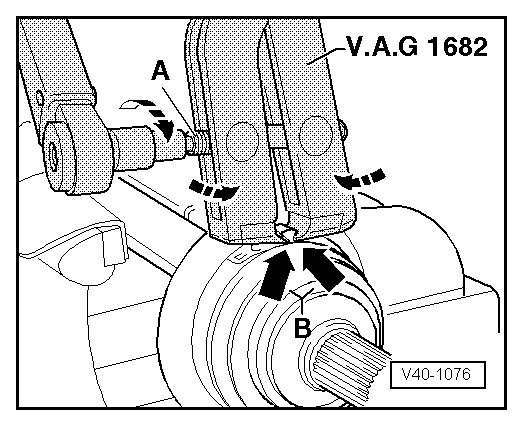

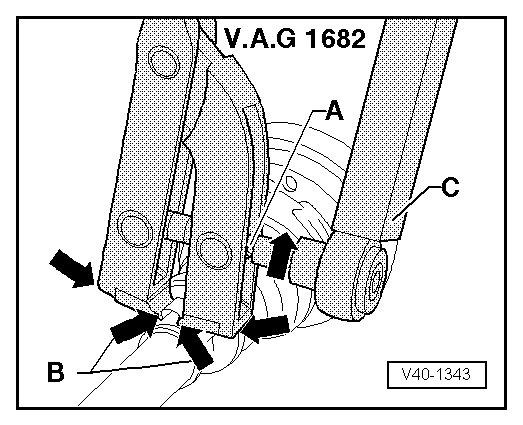

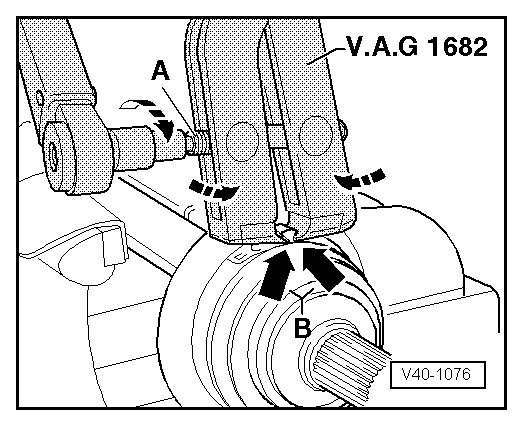

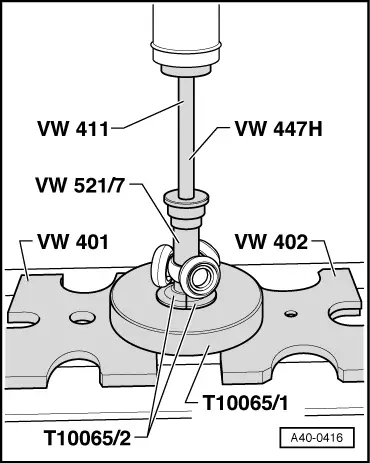

| Tightening hose clip on outer joint (large diameter) |

| –

| Apply clamp tensioner -V.A.G 1682- as shown. Ensure jaws of tool make contact with lugs -arrows B- on hose clip. |

| –

| Tighten hose clip by turning spindle with torque wrench (take care to keep clamp tensioner straight). |

Note! | t

| Due to the hard material of the CV joint boot (as opposed to rubber), a stainless steel hose clip is required; this can only be tightened using clamp tensioner -V.A.G 1682-. |

| t

| Tightening torque: 20 Nm. |

| t

| Use torque wrench-C- (adjustment range 5 ... 50 Nm), e.g. -V.A.G 1331-. |

| t

| Make sure thread of spindle -A- on clamp tensioner moves freely. Lubricate with MOS2 grease if necessary. |

| t

| If the thread is stiff (e.g. due to dirt), the required clamping force will not be attained at the hose clip when applying the specified tightening torque. |

|

|

|

Note!

Note!