| –

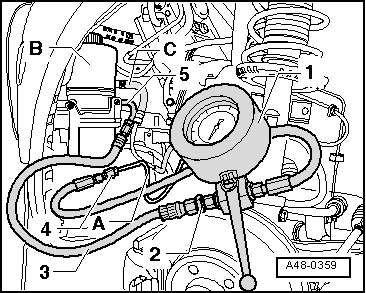

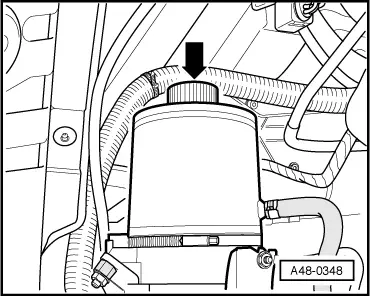

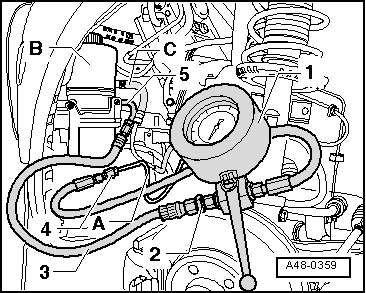

| Connect power steering tester -V.A.G 1402- |

| –

| Attach tester to front suspension. Hoses must not be under tension. |

| 1 - | Power steering tester -V.A.G 1402- |

| 2 - | Adapter -V.A.G 1402/3- |

| 3 - | Hose from adapter set -V.A.G 1402/6- |

| 4 - | Adapter -V.A.G 1402/2- |

| 5 - | Adapter -V.A.G 1402/1A- |

| –

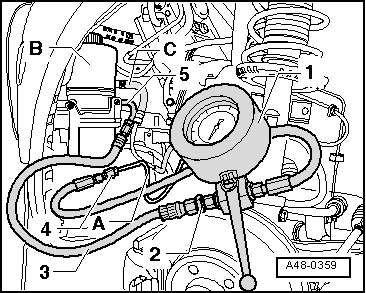

| Open cut-off valve at pressure gauge of tester. Lever must point vertically downwards. |

| –

| Fill up with hydraulic fluid and bleed steering system → Chapter. |

Note! | t

| A second mechanic is required for testing the delivery pressure/system pressure of the motor/pump unit. |

| t

| To prevent damage to the motor/pump unit and the power steering system, testing of the delivery pressure/system pressure must not be continued for longer than approx. 5 seconds. |

| t

| The cut-off valve on the pressure gauge of the tester must not be closed during the test. If the cut-off valve is closed, the displayed pressure will drop to 0 bar when the pressure valve in the motor/pump unit responds. |

| –

| Now check delivery pressure. |

| –

| Read off pressure with engine idling and steering at full lock (left and right). |

| –

| Compare measured value with specification. Specification: 96…104 bar. |

Note! | t

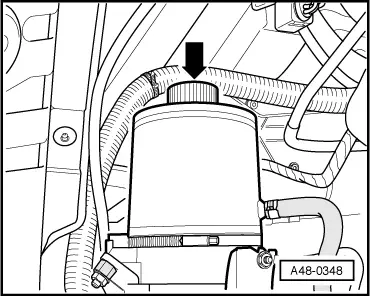

| Always check steering system for leaks if fluid level is low in reservoir. |

| t

| If leakage is visible at steering pinion, first check pipes and pipe connections for leaks. Tighten and wipe dry if necessary. |

| t

| Renew steering gear if leakage is found at steering pinion seal or at steering rack seals in steering gear housing. |

| t

| To check steering rack seals, loosen hose clip on boot and push back boot. |

| –

| Draw off hydraulic fluid with extractor bottle. |

| –

| Remove power steering tester. |

| –

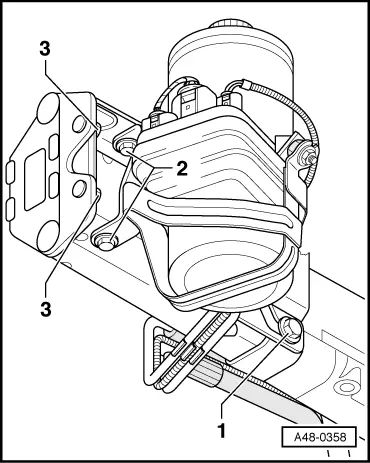

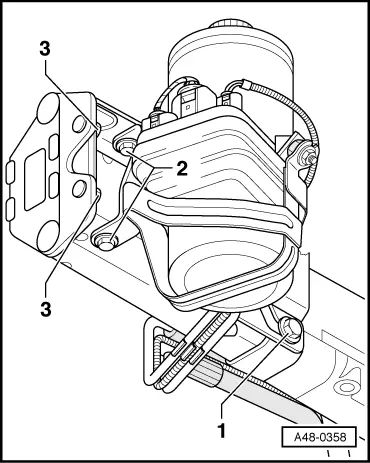

| Connect expansion hose to motor/pump unit. |

| –

| Bolt motor/pump unit with bracket or adapter to body. |

| –

| Install expansion hose, return line and wiring in spacer bracket. |

| –

| Fill up with hydraulic fluid and bleed steering system → Chapter. |

|

|

|

Note!

Note!

Note!

Note! Note!

Note!

Note!

Note!

Note!

Note! Note!

Note!