| –

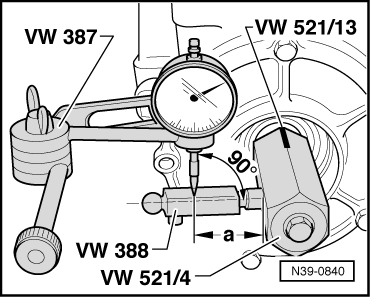

| Fit measuring tools with dial gauge extension, approx. 25 mm as shown in the illustration. |

| l

| Screw in measuring lever -VW 388- so that the dial gauge extension is at right angles to the measuring face. |

| –

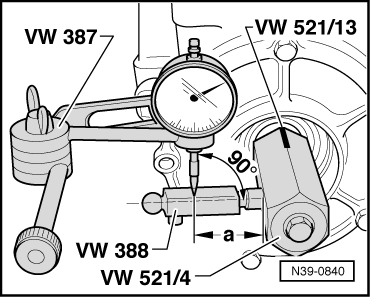

| Rotate bevel gear with input shaft until stop. Set dial gauge to “0”, turn bevel gear with input shaft back and read off backlash. Note this value. |

| –

| Loosen locking screw on clamping sleeve and turn bevel gear with input shaft through a further 90°. Then repeat complete measuring process a further 3 times. Add up the four measured values and calculate the average backlash. |

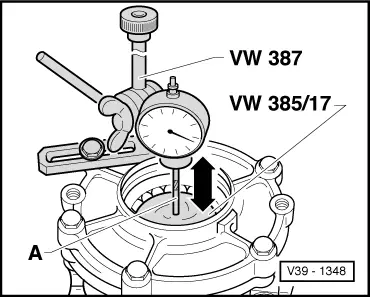

| Calculating average backlash |

|

|

|

Note

Note

Note

Note