Removing and Installing Bevel Box - Gearbox Mechanics and Operation

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

Note

Note

Note

Note

Note

Note |

|

Note

Note

|

|

|

|

|

|

|

|

|

|

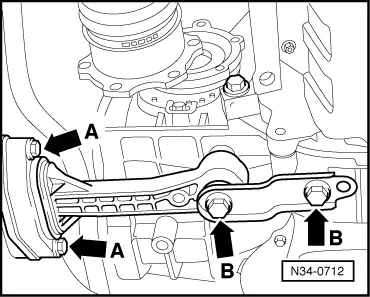

| Component | Nm | |||||||

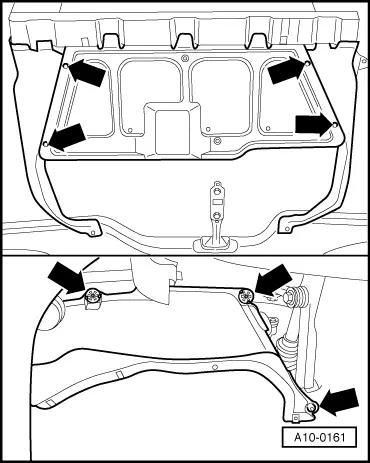

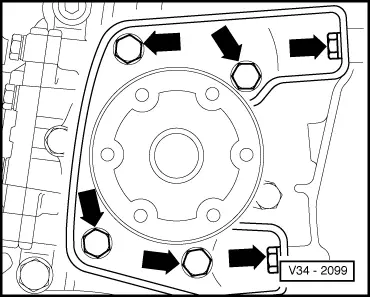

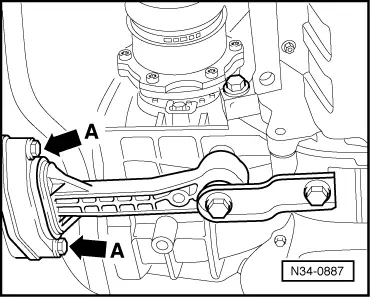

| Bevel box to gearbox | 40 + 45° 1)2) | |||||||

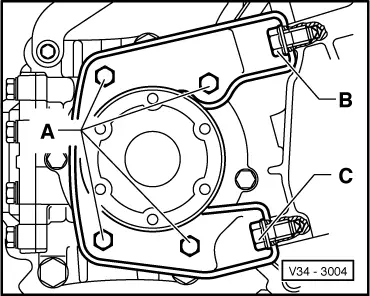

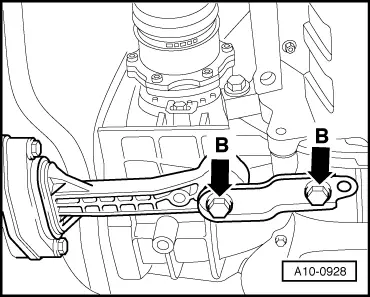

| Pendulum support to | gearbox | 40 + 90° 1)3) | ||||||

| subframe | 20 + 90° 1)3) | |||||||

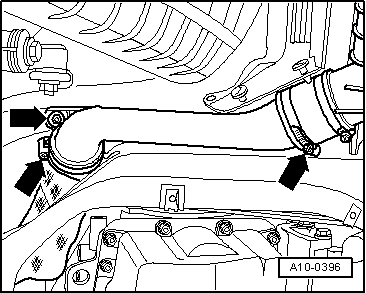

| Air pipe to longitudinal member | 10 | |||||||

| ||||||||

Caution

Caution