A3 Mk1

| Servicing gearbox housing and clutch housing |

| Special tools and workshop equipment required |

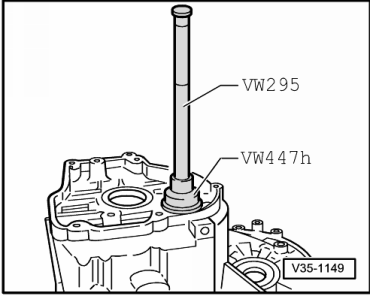

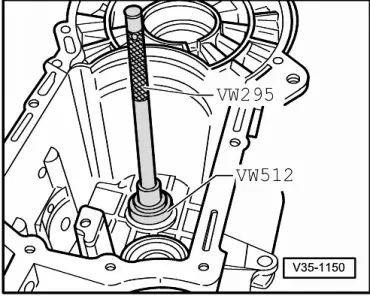

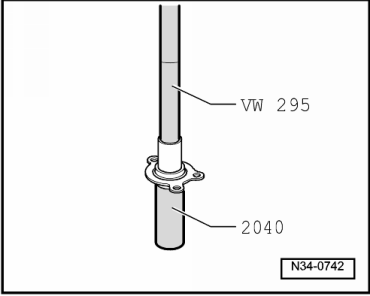

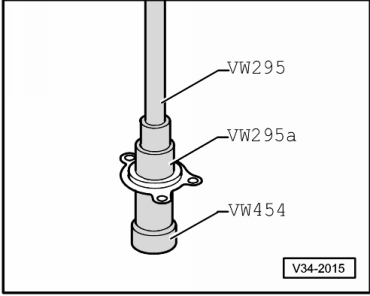

| t | Drift -VW 295- |

| t | Adapter -VW 295 A- |

| t | Thrust plate -VW 447 H- |

| t | Thrust pad -VW 512- |

| t | Tube -2040- |

| t | Press tool -VW 454- |

| t | Torque wrench -V.A.G 1331- |

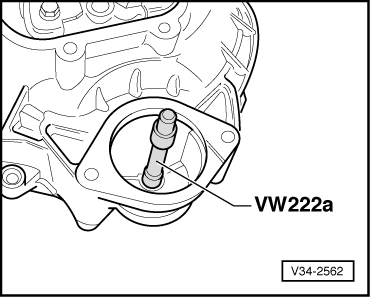

| t | Drift -VW 222 A- |

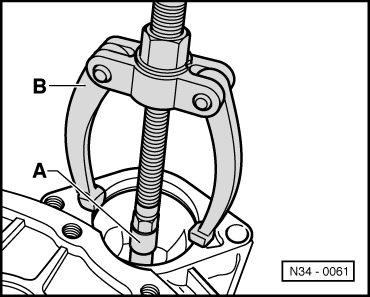

| t | -1-Internal puller -Kukko 21/1- |

| t | -4-Counter-support -Kukko 22/1- |

| Gearbox housing and clutch housing - exploded view of components |

| 1 - | Gearbox housing |

| q | If renewed: Adjust input shaft → Chapter and differential → Chapter |

| 2 - | Needle bearing |

| q | For output shaft |

| q | Removing → Fig. |

| q | Installing and securing → Fig. |

| 3 - | Oil filler plug, 30 Nm |

| q | Without magnet |

| 4 - | Shim |

| q | For input shaft |

| q | Table of adjustments → Anchor |

| 5 - | Tapered roller bearing outer race |

| q | For input shaft |

| q | Removing and installing → Fig. |

| q | If renewed: Adjust input shaft → Chapter |

| 6 - | Tapered roller bearing outer race |

| q | For output shaft |

| q | Removing and installing → Fig. |

| q | If renewed: Adjust output shaft → Chapter |

| 7 - | Shim |

| q | For output shaft |

| q | Table of adjustments → Anchor |

| 8 - | Tapered roller bearing outer race |

| q | For input shaft |

| q | Removing and installing → Fig. |

| q | If renewed: Adjust input shaft → Chapter |

| 9 - | Needle bearing |

| q | Removing and installing → Fig. |

| 10 - | Dowel sleeve |

| q | 2 x |

| 11 - | Starter bush |

| q | Can be renewed with gearbox in vehicle |

| q | Pulling out → Fig. |

| q | Driving in → Fig. |

| 12 - | Clutch housing |

| q | If renewed: table of adjustments → Anchor |

| 13 - | Guide sleeve |

| q | With input shaft oil seal and vulcanised O-ring |

| q | Knocking out oil seal → Fig. |

| q | Driving in oil seal → Fig. |

| q | Remove guide sleeve in order to renew oil seal |

| q | If O-ring is damaged, renew guide sleeve together with O-ring |

| 14 - | Socket head bolt, 20 Nm |

| q | Self-locking |

| q | Renew |

| 15 - | Speedometer drive |

| q | Tighten aluminium version to 30 Nm |

| q | Tighten plastic version to 10 Nm |

| 16 - | Oil drain plug, 30 Nm |

| q | Without magnet |

| 17 - | Tapered roller bearing outer race |

| q | For differential |

| q | Pressing out → Fig. |

| q | Pressing in → Fig. |

| q | If renewed: Adjust differential → Chapter |

| 18 - | Magnet |

| q | Held in place by joint surface of housing |

| 19 - | Tapered roller bearing outer race |

| q | For differential |

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| q | If renewed: Adjust differential → Chapter |

| 20 - | Shim |

| q | For differential |

| q | Table of adjustments → Anchor |

| 21 - | Oil seal |

| q | Renewing → Chapter |

|

|

|

|

|

|

|

|

|

|

|

|