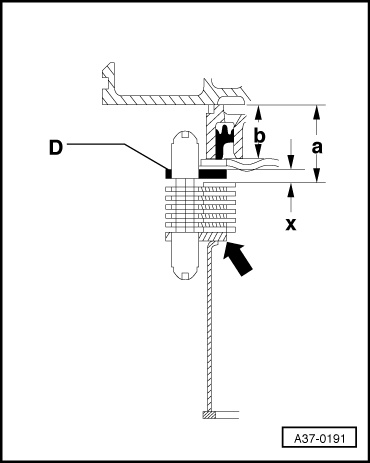

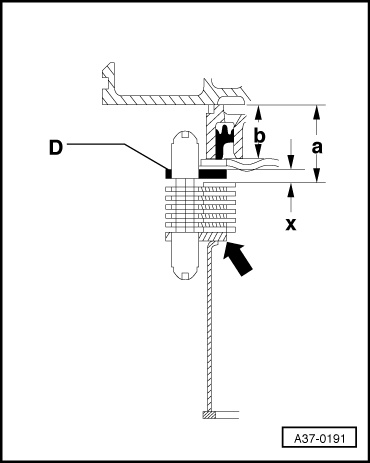

| Determining thickness of last outer plate -D- |

| The thickness of the outer plate(s) is governed by gap dimension -x-. This gap dimension is calculated according to the following formula: |

| a - | Installation position of 2nd and 4th gear brake “B2”; determining value → Anchor |

| b - | Size of ATF pump housing; determining value → Anchor |

Note | t

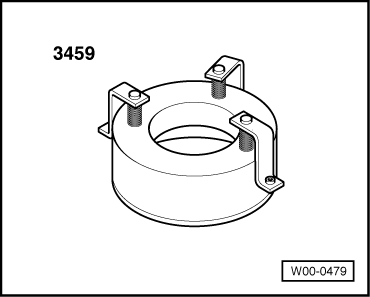

| The illustration shows a sectional view of the assembled brake “B2”. The setting tool -3459- that is used to exert a force on the clutch pack is not shown. |

| t

| The value of “3.6 mm” takes into account the settling of the plates due to the force exerted by setting tool -3459-. |

| t

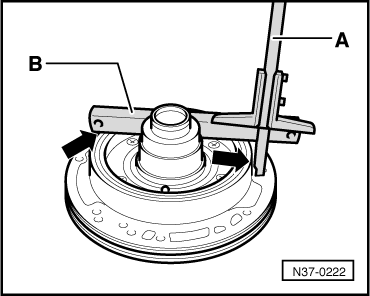

| The first outer plate -arrow- is 3 mm thick. |

| –

| Assemble planetary gearbox as far as last inner plate for “B2” → Chapter. |

Note | The last outer plate, the last 3 spring caps and the corrugated washer are not installed. |

| –

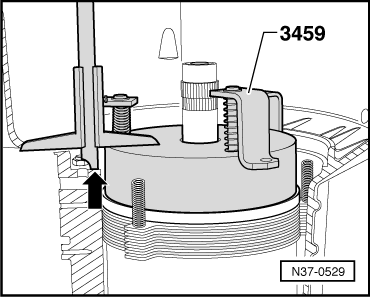

| Apply setting tool -3459- to the last inner plate and turn so that the 3 clips align with the 3 holes for the ATF pump. |

| –

| Bolt setting tool -3459- to flange for ATF pump: tightening torque 5 Nm. |

Note | The clutch pack for “B2” is now pressed together for the measurements. |

|

|

|

Note

Note

Note

Note Note

Note Note

Note