A3 Mk1

|

Removing and installing parts of the cooling system

Removing and installing coolant pump

|

|

|

|

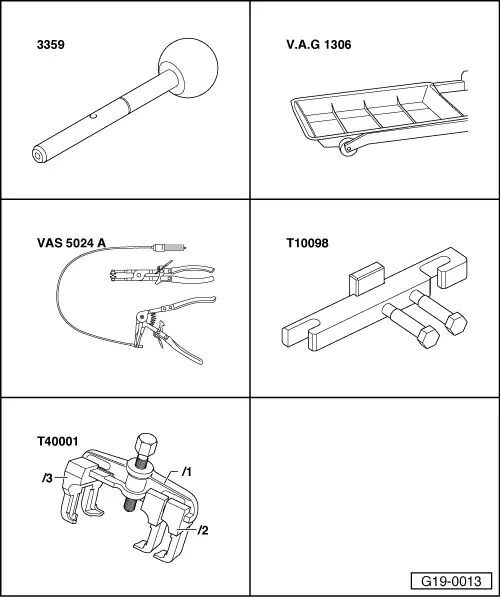

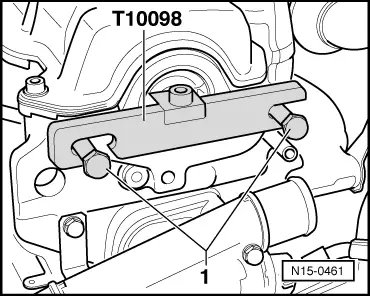

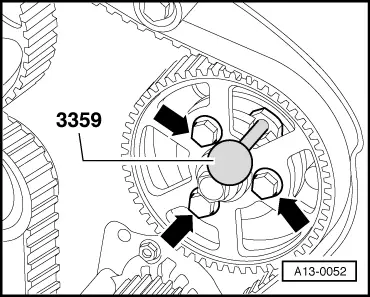

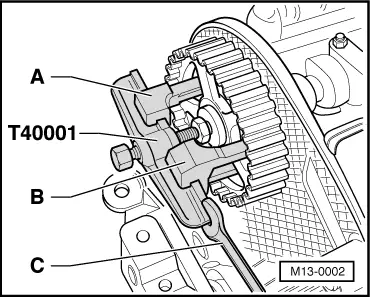

Special tools and workshop equipment required

|

|

|

|

Removing

Important

Hot steam or hot coolant can escape when opening expansion tank. Cover cap with a cloth and open carefully.

|

|

|

|

|

|

|

|

|

|

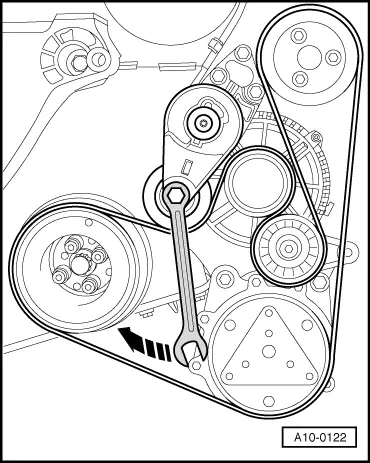

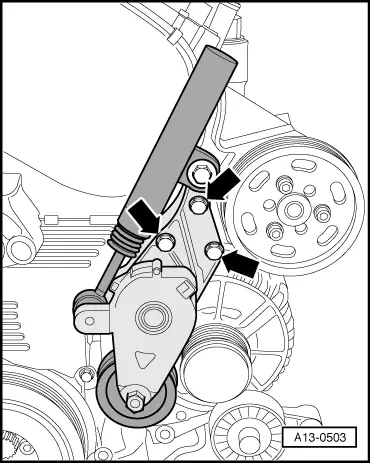

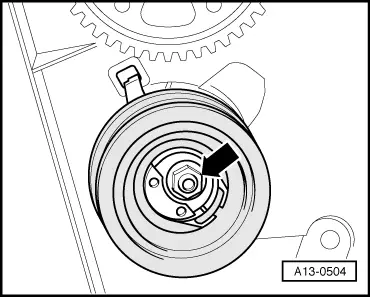

Note: Mark the running direction with chalk or a felt-tipped pen before removing the ribbed belt. If the belt runs in the opposite direction when it is refitted, this can cause breakage.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

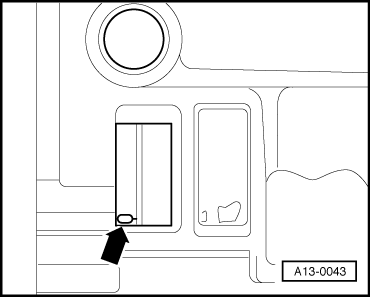

Note: Position crankshaft to TDC No. 1 cylinder with engine removed. |

|

|

|

|

|

|

|

|

|

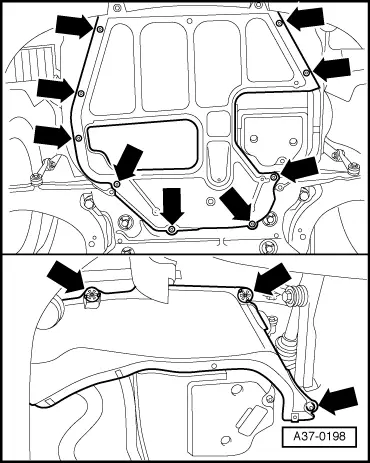

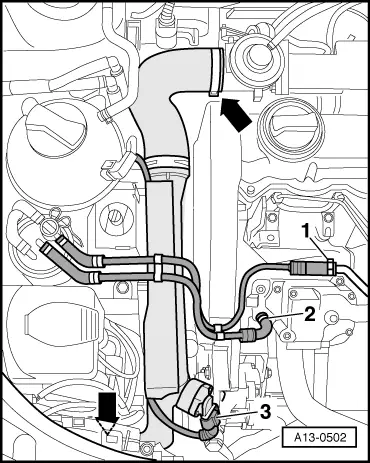

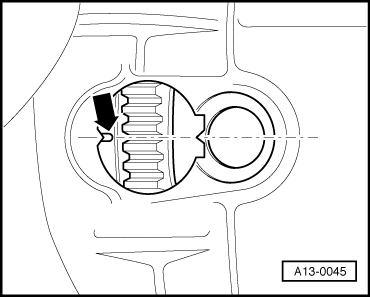

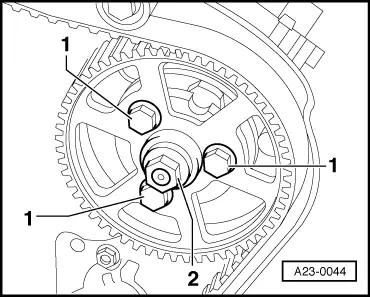

Note: → Never loosen the injection pump sprocket centre nut -2-. Otherwise the injection pump basic setting is incorrectly adjusted and cannot be corrected again using workshop equipment. |

|

|

|

|

|

Notes:

|

|

|

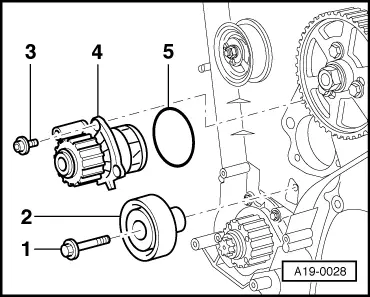

Installing Installation is carried out in the reverse order; note the following: Notes:

=> Parts List |

|

||||||||||

Note: Observe all instructions on removing and installing the toothed belt =>from Page 13-23. Tightening torques

1) Replace bolt 2) 90°corresponds to a quarter of a turn | ||||||||||