| –

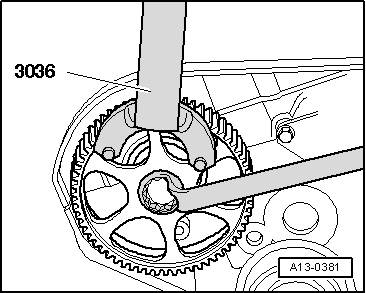

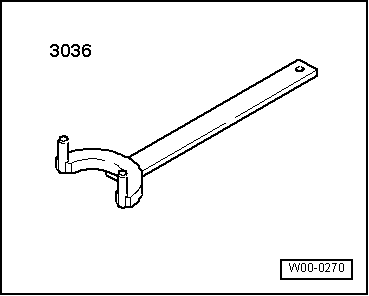

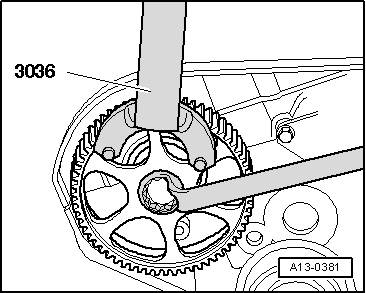

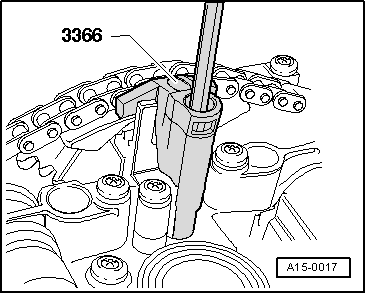

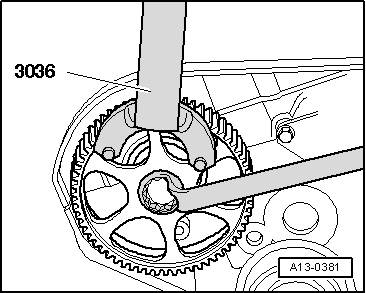

| Tighten securing bolt of camshaft sprocket (use counterhold tool -3036-). |

| –

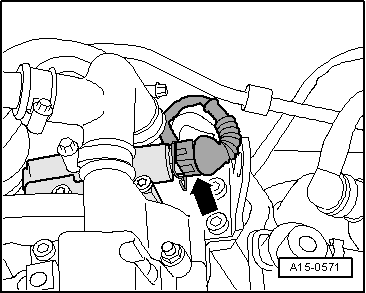

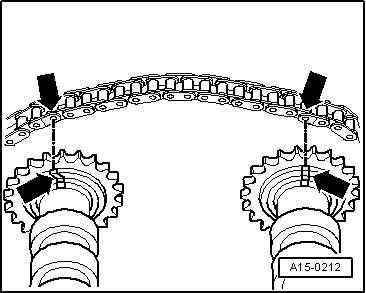

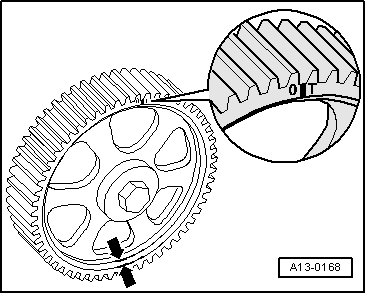

| Turn crankshaft approx. 45° clockwise to TDC position via securing bolt for toothed belt sprocket. |

| –

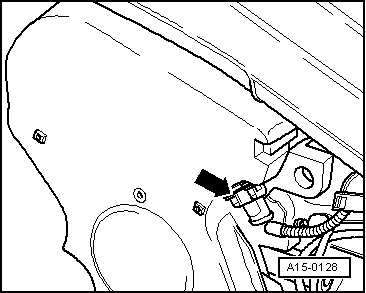

| Install toothed belt (adjust valve timing) → Anchor. |

Note | t

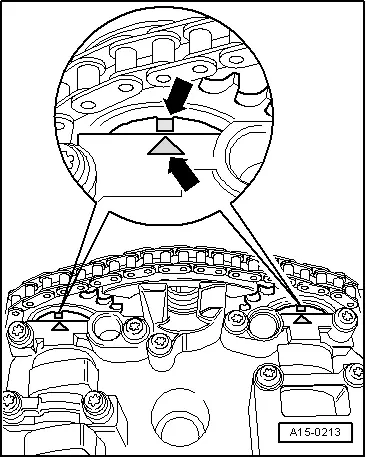

| After installing camshafts, wait for approx. 30 minutes before starting engine. Hydraulic valve compensation elements have to settle (otherwise valves will strike pistons). |

| t

| After working on the valve gear, turn the engine carefully at least 2 rotations to ensure that none of the valves make contact when the starter is operated. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution