| Component | Nm |

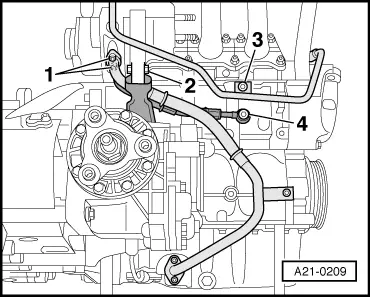

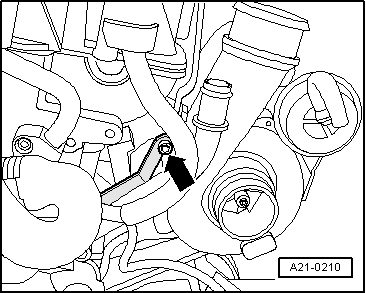

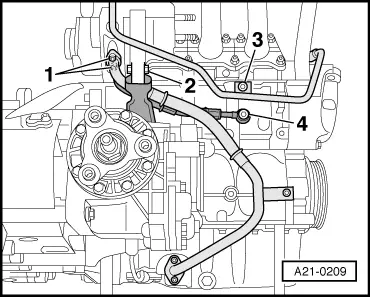

| Coolant supply pipe to: | Turbocharger | 30 |

| Cylinder block | 35 |

| Mounting bracket for coolant supply pipe to turbocharger | 10 |

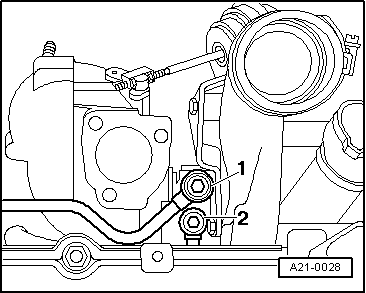

| Coolant return pipe to: | Turbocharger | 35 |

| Cylinder block | 20 |

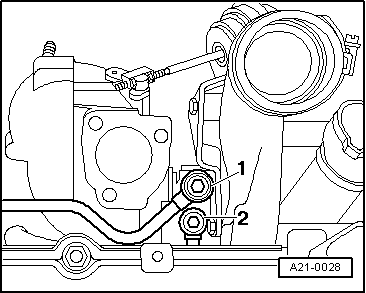

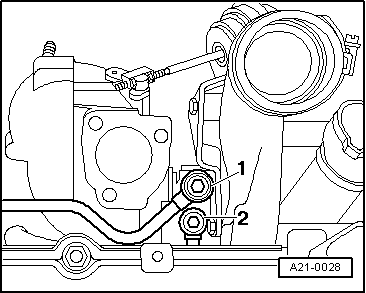

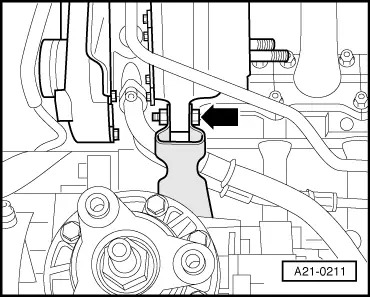

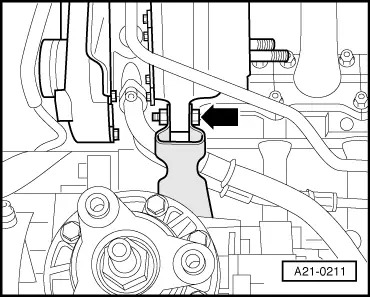

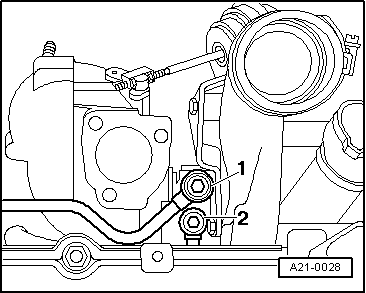

| Oil supply pipe to turbocharger | 30 |

| Bracket for oil supply pipe to turbocharger | 10 |

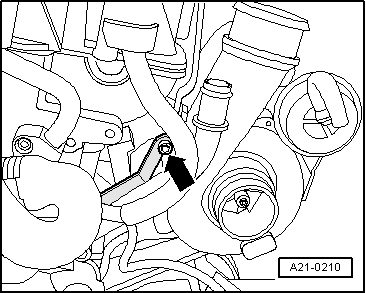

| Oil return pipe to turbocharger | 10 1) |

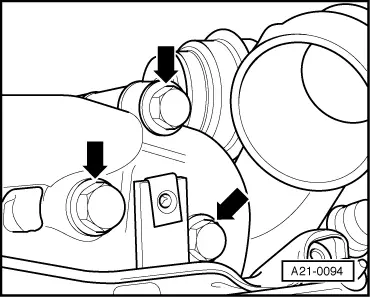

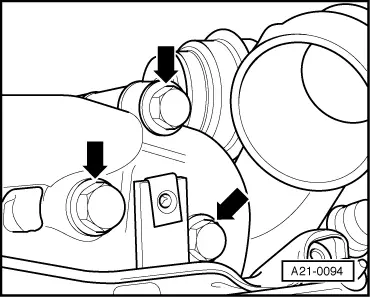

| Turbocharger to exhaust manifold | 30 2)3) |

| Bracket for turbocharger to turbocharger | 30 |

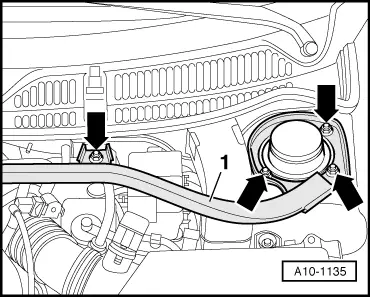

| Hose clips for air hoses | 3.5 |

| l

| 3) Coat threads and contact surface of bolt heads with high-temperature paste; for high-temperature paste refer to → Parts catalogue. |

|

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

WARNING

WARNING