A3 Mk1

|

Removing and installing parts of the lubrication system

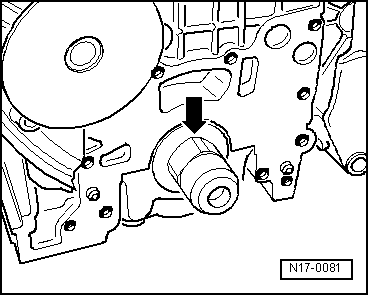

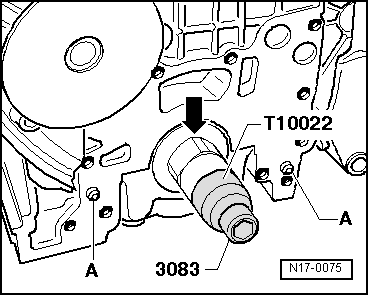

Removing and installing oil pump

|

|

|

|

Removing

|

|

|

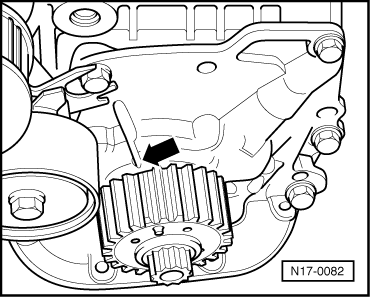

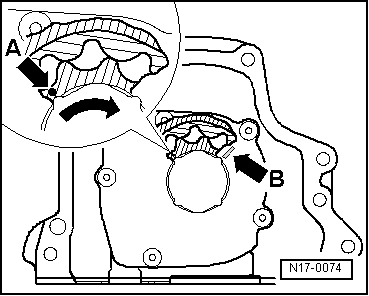

Note: This procedure moves the crankshaft to the correct installation position for the oil pump. One of the polygon cams on the crankshaft is uppermost. |

|

|

|

|

|

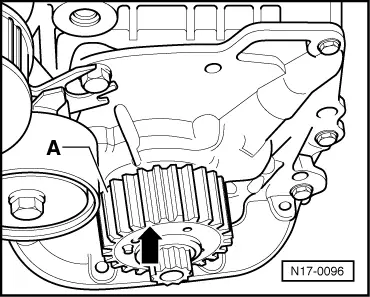

Installing Conditions

|

|

|

|

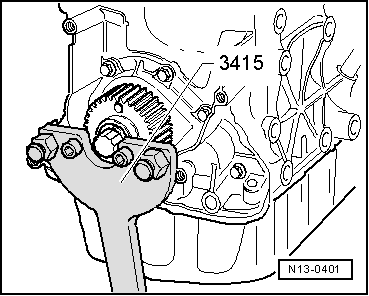

Work sequence

|

|

|

Installing toothed belt and adjusting timing. |