A3 Mk1

|

Removing and installing parts of the lubrication system

Removing and installing oil sump

Special tools, workshop equipment, testers, measuring instruments and auxiliary items required |

|

|

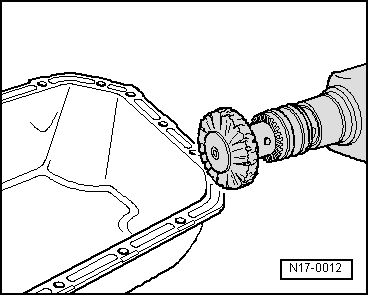

Work sequence

=> General body repairs, exterior; Repair group 50; Front body; Noise insulation - Assembly overview Vehicles with drive unit protection plate

=> General body repairs, exterior; Repair group 50; Front body Continuation for all vehicles

Note: Observe disposal regulations!

|

|

|

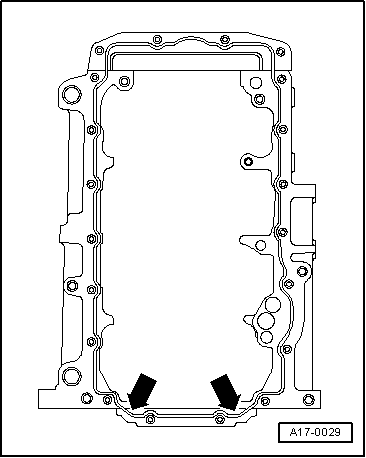

Installing Notes:

|

|

|

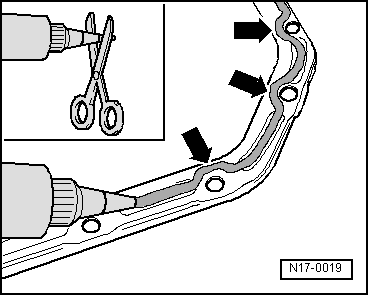

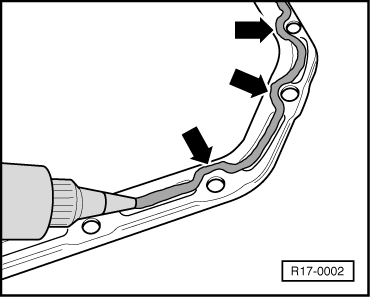

Note: The sealing compound bead must not be thicker, otherwise excessive sealing compound will enter the sump and may block the oil suction pipe strainer. |

|

|

|

|

|

Note: The sealing compound bead must not be thicker, otherwise excessive sealing compound will enter the sump and may block the oil suction pipe strainer.

Note: After installing sump the sealant must be allowed to dry for approx. 30 minutes before engine oil is replenished. |