A3 Mk1

|

Servicing valve gear

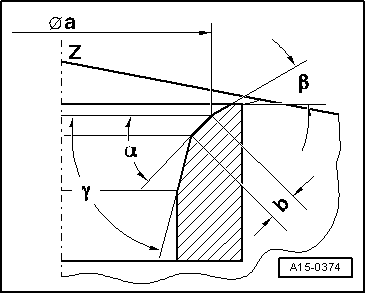

Reworking valve seats

Note: If a good seating pattern cannot be obtained by grinding the valve seats (lapping), they must be refaced (reworked): Special tools and workshop equipment required

Notes:

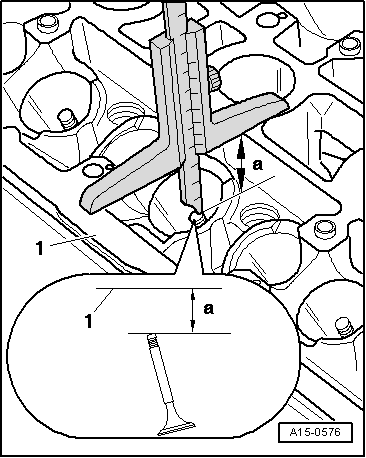

Calculating maximum permissible reworking dimension

Note: If the valve is to be renewed as part of a repair, use a new valve for the calculation. |

|

|||||||||||||||||||||||||||

Measured distance minus minimum dimension

Note: If the maximum permissible reworking dimension is 0 mm or less than 0 mm, repeat the measurement with a new valve. If the measured result is again 0 mm or less than 0 mm, renew the cylinder head. | |||||||||||||||||||||||||||