A3 Mk1

| → Indicated on display: (1...10 = display zones) |

|

||

Do not continue with the test until the coolant has reached the specified temperature. |

|

|

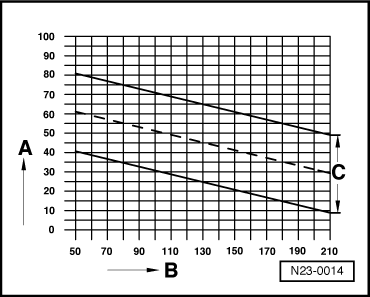

Note: If injection start is within specified range C when tested, no adjustment is required. If the commencement of injection is outside the specified range, adjust the injection pump as follows:

If the markings are not aligned:

|

|

|

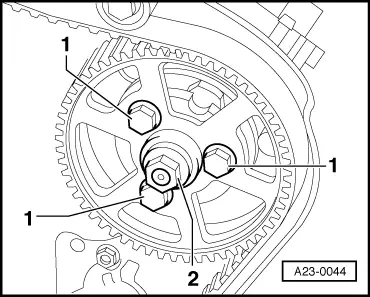

Note: Do not undo hub nut -2-. Otherwise the injection pump basic setting is maladjusted and cannot be corrected using workshop tools.

Note: The securing bolts are stretch bolts and can therefore only be used once.

If injection start is outside tolerance range:

|